Portion control: Not green?

Portion control is an inherent part of single-serve packaging for frozen food. However, individualized portions can go up against another important trend in food packaging: sustainability. Single-serve foods, especially small portions like snacks as opposed to full meals, end up using more packaging, says Esther Palevsky, an industry analyst with the consulting firm Freedonia Group.“You’ve got dynamics that are kind of going up against each other,” Palevsky says. “The popularity of single-serving products-people want things that are portable-those tend to use more packaging. But you want less packaging, Wal-Mart wants less packaging, so there’s both of those things going on at once.”

One possible solution is the use of reclosable features in frozen and refrigerated packaging. The Pillsbury unit of General Mills, for instance, pioneered a flexible bag with a reclosable adhesive strip for its frozen dinner rolls. Packaging like this encourages the products’ use by smaller households, because consumers can just take out as many or as few rolls as they want.

A report Palevsky authored for Freedonia predicted that, although rigid packaging like paperboard boxes and trays will continue to predominate in frozen food, the use of flexible packaging will grow faster over the next few years. Not only do stand-up pouches save space; they’re still unusual enough, especially for meat and other entrees, to increase their shelf appeal through novelty value.

Frozen foods have in many cases tried to reduce the overall amount of packaging material they use. This appeals to environmentally conscious consumers as well as saving money. One example is the line of all-natural frozen foods from the Kashi unit of Kellogg Co. Kellogg lightweighted the overall packaging of Kashi’s frozen-food line by 11%, including film, trays, folding cartons and cases; the primary packaging for frozen foods has been decreased by 14%.

Natural appeal

Appealing to consumers’ desires for “fresh” or “natural” products can be an important aspect of prepared-meals packaging. This can be especially vital with refrigerated meals, which have the inherent advantage of being seen as less “processed.”One of the most common ways for packaging to push that advantage is to let the consumer see the product. Refrigerated food simply looks more appetizing than frozen. Windows for paperboard packaging and clear film for flexible can help show product off.

One example of refrigerated food with packaging that carries the natural motif is Natural Choice sliced deli meats from Hormel Foods. The products, including bacon and oven-roasted chicken strips, use kraft paperboard cartons for a down-to-earth appearance. The cartons have die-cut windows and vacuum-shrink interior packaging that shows off the product to best advantage, especially the carved whole-muscle meats.

“This packaging design was chosen because there was a connection with our consumers between an all-natural, great tasting product and packaging that was Earth-friendly and had a natural look and feel,” says product manager Ryan Vossler.

Another new Hormel product, sold through supermarkets’ deli departments, is taking convenience to a new level. Deli Entrées, including chicken breasts, pork roasts and meat loaf, arrive at the supermarket in cooked form, as part of a kit complete with domes and sleeves. They are heated in the package and assembled by store personnel, who apply domed lids and paperboard sleeves with handles. Deli Entrées are sold alongside rotisserie chickens with matching packaging.

Getting graphic

Frozen foods don’t have the advantage of refrigerated foods of looking good before they’re heated, Palevsky points out. This means they have a lot more riding on their graphics. “Frozen foods, when you take them out, the way they look frozen, they’re really not that appealing in most cases,” she says. “I think the packaging is really important because it can illustrate how it’s going to look.”That can be especially important because of an inescapable fact in the frozen food industry: brutal price competition. Years of price wars have conditioned consumers to expect near-complete meals for a few dollars a serving.“I remember hemming and hawing over spending five bucks for a [private label] spinach and walnut ravioli, and it was terrific,” Palevsky says. The point is that top-notch graphics for a premium product are vital in overcoming consumer reluctance to invest in a premium frozen product. Packagers of such products might do well to look into high-end printing techniques like rotogravure, eight-color presses or reverse-print top layers for laminated film.

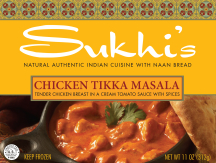

Graphics are especially important when introducing products with which American consumers are unfamiliar. That’s what Sukhi’s Gourmet Indian Foods, a 15-year-old ethnic food company, determined when it redid the packaging for its line of Indian frozen food. Indian cuisine is far more popular in the UK than in the U.S., and consumers require education, says Sanjog Sikand, sales and marketing director.

“From a pure packaging perspective, the number-one thing that we learned is important is picture, picture, picture,” Sikand says. Working with design firm Gauger + Associates, the company used a food stylist to create an image that was appetizing and yet reflective of what’s in the package. The graphic message was completed with a Mughal art motif with a yellowish-orange color; “The packaging needs to speak ‘intricate and exotic,’” Sikand says.

Functional features

Packaging, of course, can do more for frozen food than put pretty pictures on the front. Functional features can enhancing the flavor and quality of frozen food.Susceptors are metallized components on package interiors that attract heat and bring it into direct contact with food. They have been long used on certain kinds of frozen foods; one supplier says that 90% of all frozen pot pies sold in North America use susceptors to brown the crust during microwave heating.

Susceptors have been moving into new products. Last year H.J. Heinz Co. introduced them for single-serve packaging for two of its established bite-sized snacks: Delimex taquitos and Bagel Bites mini bagels with toppings. The susceptor-equipped boxes, dubbed Crisp & Carry, allow consumers to microwave a single serving of snacks (five taquitos or six Bagel Bites) and have them come out with browned surfaces.

A somewhat more sophisticated example of susceptors can be seen in Deli Creations, from the Oscar Mayer unit of Kraft Foods. The refrigerated kit includes all the components of a sub sandwich: meat, cheese, bread and condiments. After assembling the sandwich, the consumer microwaves it in a paperboard-based tray with laminated quilting. The quilted pockets expand, contacting the product, while the tiny crevices between the pockets allow moisture to escape, so that the bread (which is specially formulated) browns without becoming soggy.

Another significant operational innovation in frozen food involves steaming. Birds Eye Steamfresh, Green Giant Simply Steam and others use flexible packaging with vents that release built-up steam to ensure even heating of frozen vegetables. When combined with value-added formulations, such as unique vegetable combinations with special sauces, the steam-in-bag technology can represent a significant boost beyond simply marketing vegetables as commodities.

One of the most sophisticated new products using steam technology is the Café Steamers line from ConAgra’s Healthy Choice unit. Café Steamers use unique packaging to apply different heat intensity to three components of a frozen entrée: meat or fish, starch (rice or pasta) and sauce.

The packaging consists of an inner plastic bowl with vents along the side, nestled inside a solid-sided bowl with the sauce on the bottom. As the food heats in the microwave, the sauce-infused steam circulates throughout the food in the inner bowl. The consumer then deposits the food into the bowl with the sauce for the final presentation.

“We constantly hear from consumers that frozen foods have a freshness barrier, and when looking at different cooking techniques to overcome this barrier, steaming was the right option as it is seen as a cooking technique that unlocks the naturally fresh flavors of each ingredient,” says Bill Partyka, vice president of marketing for Healthy Choice.

As prepared foods become more versatile, packaging is going to have to do more, both functionally and in terms of educating the consumer. Taking full advantage of the opportunities to do so will greatly increase the chances for a new product’s success. F&BP