MG America (mgamerica.com), the U.S. subsidiary of MG2 of Bologna, Italy and a leading supplier of processing and packaging equipment, will showcase a variety of premium equipment at Pharma Expo Las Vegas, September 28-30. At the show, MG America will exhibit an innovative wheeled bin mixer manufactured by COS.MEC, an Italy-based supplier of dispensing, granulation, mixing, loading and washing equipment; a multi-purpose cartridge filler for aseptic conditions manufactured by Steriline, for which it is a distributor in the U.S. and Puerto Rico; and the Planeta continuous motion capsule filler with overencapsulation capabilities.

COS.MEC’s wheeled bin mixer is a sophisticated piece of equipment used for mixing pharmaceutical powders and granules inside the bin, which eliminates the need for loading, unloading and cleaning the mixer. Its main features include:

- Bin manual lock

- Single inclination

- Both clockwise and counter-clockwise bin rotation

- Bin speed adjustment by inverter

- Possibility of receiving bins of different volumes

- Remote control panel with manual setup of mixing speed and time

- Fixing to floor only

Optional features include bin double inclination, remote control panel for the automatic programming and printing of process parameters by PLC + touch screen + printer, a barcode reader for batch automatic identification, and the ability to handle non-standard bins, among others.

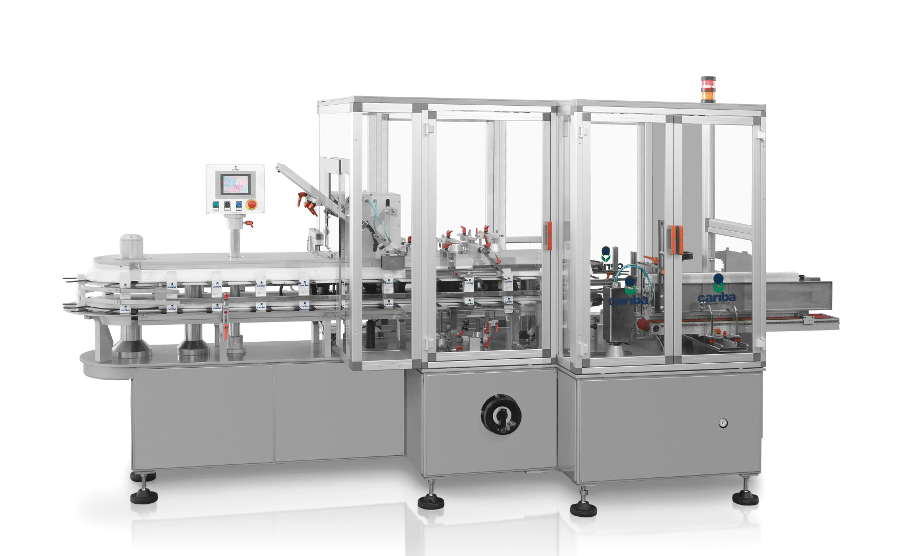

MG America also will be touting its new strategic partnership with Italy-based cartooning machine manufacturer Cariba. Under the agreement, MG America will supply Cariba’s premium line of cartoners to markets in the U.S., Canada and Puerto Rico, as well as assume customer service responsibilities including pre-installation inspection, line integration and ongoing maintenance duties. At Pharma Expo, MG America will exhibit the Cariba 230 (C230), a machine known for its flexibility and ease of use that can make up to 80 boxes per minute. The compact and reliable top-load cartoner is designed for manual or automatic product feeding. Highlights include:

- Two or four operators configuration feeding station

- Positive carton forming

- Fast change over, mainly based on adjustments

- Tuck-in and/or hot melt closures

- Emboss or ink-jet coding

- Pre-folded leaflet insertion

- Barcode reading capabilities

Other machines to be showcased by MG America at Pharma Expo La Begas include:

The Steriline Cartridge Filler Model VKSFCM50 is a filling solution designed to achieve flexibility for multi-purpose filling under aseptic conditions. It enables users to handle all components on a single machine in a single room, resulting in a reduction in capital cost as well as validation and operational costs. The cartridge filler has controls for no-container, no-fill, reject of any container with missing stopper, missing alu-cap or wrong fill volume, and includes a user friendly touch screen HMI.

MG America’s Planeta Capsule Filler features a modular design allowing for different dosing units to be filled at the same time. It can fill powders, pellets, microtablets, tablets, liquids, or herbal products in single or multiple doses and in all kinds of combinations. Low-dose powder applications can be accommodated and capsules can be filled with up to four different types of pellets. The filler’s speed ranges from 6,000 to 200,000 capsules per hours, and no parts need to be changed to accommodate different tablet shapes and sizes. It also has a touch screen control panel and a built-in fill-weight verification system.