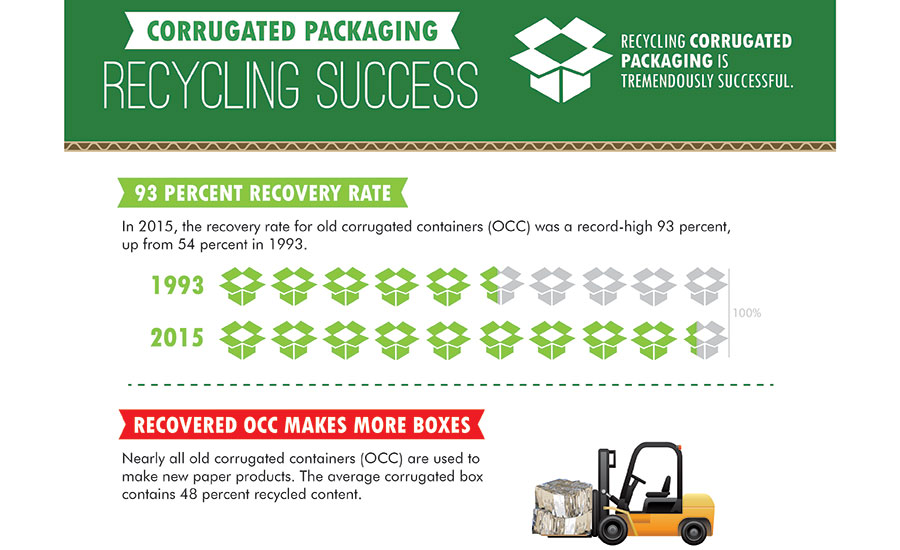

The corrugated industry has recorded new high points in corrugated recycling. Newly collected statistics show that the old corrugated containers (OCC) recovery rate hit an all-time high of 93% in 2015. The Corrugated Packaging Alliance (CPA) also announced a rise to 48% in the average recycled content of corrugated boxes. That’s higher than previous estimates, and an important part of corrugated’s sustainability record.

Corrugated’s recovery and reuse rates have long been ahead of other packaging materials’ rates, but it didn’t happen overnight. It took a prolonged and focused industry effort whose success can serve as an example to improve recycling rates for other packaging materials.

Symbolism

Way back in 1970, Wisconsin Senator Gaylord Nelson created Earth Day to build Americans’ awareness and appreciation for the environment. At the same time, a corrugated company called Container Corporation of America (CCA) sponsored a contest to design a symbol promoting their products made from recycled materials. Gary Anderson, a student from the University of Southern California, submitted the winning entry that CCA modified and introduced to the world. That symbol is the familiar “chasing arrows” universally recognized as the recycling symbol today.

The corrugated industry innovated again in the early ’90s, developing the Corrugated Recycles symbol to help people identify corrugated for recycling. At the time, curbside recycling was new to most communities. Raising awareness of corrugated’s recyclability was an important first step to increase its recovery rate. Later adopted internationally, the Corrugated Recycles symbol is printed on the bottom of a significant number of today’s corrugated boxes as a clear sign that the package can be recycled.

It worked. The percentage of corrugated recovered for recycling has been climbing steadily since the symbol’s adoption, and grew 3.7 percentage points in 2015 over the year before to the record-high 93%. The 2015 increase was driven by a 3.5% increase in domestic consumption of recovered fiber and a 10.6% jump in OCC exports, as reported in the American Forest & Paper Association (AF&PA) annual report on U.S. paper recovery. (More statistics are available at www.paperrecycles.org/statistics.)

This is just the latest improvement resulting from the corrugated industry’s long-term efforts. Even back in 1993, when recycling first began in earnest, 54% of corrugated was being recovered – a significant achievement already, considering less than 15% of plastic is recovered today, more than two decades later.

Where Does OCC Go?

Most recovered OCC is used to make new paper products. More than 51% of OCC recovered in 2015 was used to make new containerboard for more corrugated boxes. An additional 11.5% was used to make boxboard (for primary packaging like cereal boxes), and more than 32% was exported. Global demand for OCC generated in the U.S. has grown steadily as well, helping ensure a viable market for U.S. recovered fiber.

Corrugated Recycles

For more information: Visit www.corrugated.org to download a new infographic and white paper detailing the rise in corrugated recycling. Follow CPA on Twitter at @corrugatedpkg.