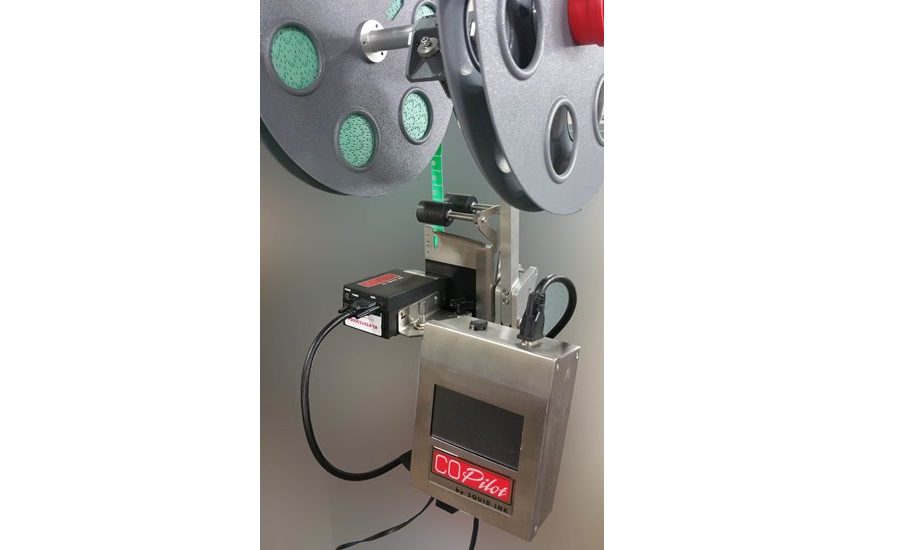

Squid Ink Manufacturing (squidink.com) in partnership with Kwik Lok Corporation (kwiklok.com) announces the release of the new 905A CoPilot UV LED Printer. The 905A CoPilot UV LED is designed to be attached to the Kwik Lok® 872 Automatic Bag Closing Machine, utilizing the CoPilot printer and UV LED Curing System built by Squid Ink Manufacturing. The new system offers immediate cure time and clean, crisp codes on the Kwik Lok bag closure, resulting in a low maintenance system with low overall cost of ownership.

The CoPilot UV LED curing and printing system from Squid Ink offers accurate and consistent UV curing across a variety of commercial and industrial applications. UV cure ink is a non drying, minimal maintenance ink cured by LED light. This instant LED curing ink is impervious to environmental factors such as sunlight, water, moisture, temperature, and contains virtually no VOC’s, making it ideal for bakery applications. The 905A CoPilot system utilizes easy-to-use software modified specifically for the baking industry for easy message programming and message recall.

In the near future, the 905A will be released with the Kwik Lok 893 and 865 closure systems for use in the produce and bakery industry.

The Kwik Lok 872 Automatic Bag Closing Machine enables the packager to close and label bagged packages with one machine at speeds up to 105 per minute. The system will close a wide range of product size variations. Striplok® closures are available in many closure opening sizes to accommodate a large number of bag widths and film thicknesses. The 872 features an operating panel for speed control (0 to 105 bags/min), a shift counter, lifetime counter, and a manual cycle button.

The Kwik Lok 905A CoPilot UV LED is available now through Kwik Lok’s worldwide network of authorized distributors.