The future of the biaxially oriented polyamide (BOPA) film market looks bright, with opportunities including in the packaging, automotive, construction and electrical industries, according to a report by Lucintel (lucintel.com). The global BOPA film market is expected to reach an estimated $3.4 billion by 2022 and is forecast to grow at a CAGR of 8.8% from 2017 to 2022. Major drivers for this market are increasing demand for flexible packaging due to the growth in food & pharmaceutical market and superior mechanical strength, higher transparency, chemical resistance and excellent gas barrier properties, compared to biaxially oriented polypropylene (BOPP) and biaxially oriented polyethylene terephthalate (BOPET) film.

Sequential, simultaneous, and blown process are used to produce BOPA films. Lucintel forecasts that the sequential process is expected to remain the largest segment due to low-cost, flexibility in the process while stretching and high production rate. Simultaneous process is expected to witness the highest growth due to the increasing demand for high value BOPA films for advanced applications, such as retortable pouches.

Within the BOPA film market, food packaging is expected to remain the largest end use industry; it is also expected to witness the highest growth during the forecast period, supported by the growth in demand for processed meat, red meat, and cheese packaging. Lucintel predicts that the demand for BOPA films in barrier functions is expected to remain the largest segment and see the highest growth supported by superior protection properties, such as loss from aroma, permeation of water, increases shelf-life, maintain taste.

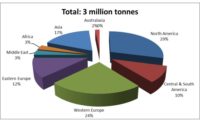

Asia Pacific is expected to remain the largest market by value and volume and is also expected to witness the highest growth over the forecast period because of growth in the demand for food and pharmaceutical packaging, automobile, and construction sectors due to economic expansions in India and China.

Emerging trends, which have a direct impact on the dynamics of the industry, include growing use of linear simultaneous stretching line (LISIM) technique and growing demand for balanced film with better dimensional stability and less shrinkage.