Inspection/Detection/Vision

Machinery

ISRA VISON, Bosch Rexroth and Teledyne TapTone are among companies offering much-needed inspection and detection technology to the packaging industry

Read More

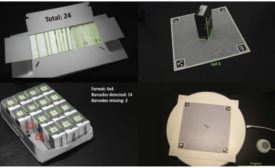

Package Detectability

Technology Advances X-ray and Metal Detector Inspection Capabilities

Metal detectors and X-ray machines both have a place on the production line, and different packaging types and products can affect their performance.

March 30, 2021