A decade ago many analysts cited connected enterprise software — Internet of Things (IoT) — for converters and package printers as marketing hype and not worth the investment. The criticism centered around latency data network issues, pricey software and integration challenges for smaller companies.

Well, those analysts were wrong. Advanced prepress and connected information system solutions are arriving for converters and label printers at precisely the right time, as last year’s pandemic showed.

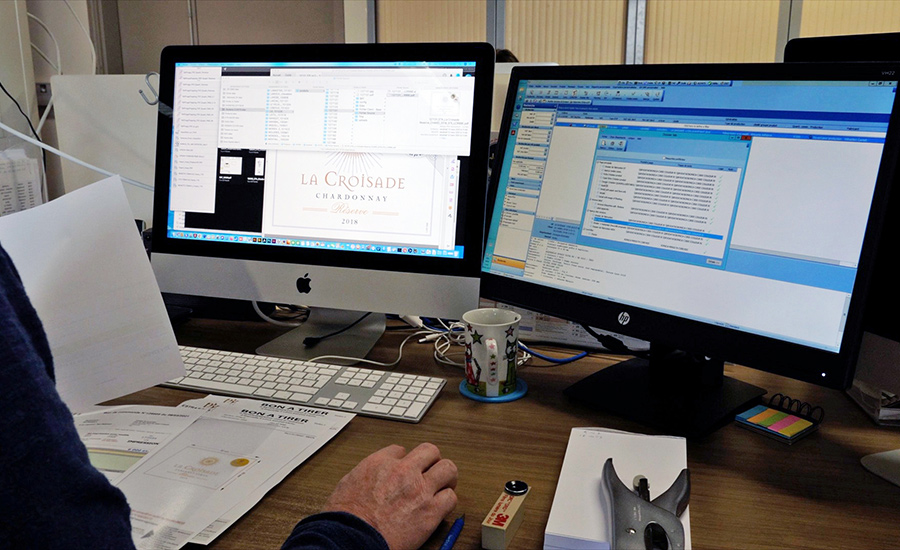

Estrabols Imprimeur is one of the companies that saw the promise of connected platforms and data uniformity flowing through its entire enterprise, from customer to printing. Today, the company is running Esko’s workflow optimization solution Automation Engine and CERM’s management information system (MIS) to create an integrated solution that allows the company to focus on future growth and operational scalability.

The label printer was founded in 1934 and is located in the heart of southern France’s viticulture and wine making industry. This fourth-generation company employs approximately 40 dedicated operator specialists within its 29,000-square-foot (2,700-square-meter) printing plant, and runs many types of equipment, including three CODIMAG Viva 340 presses, an HP Indigo 6900 press with ABG Digicon and a Heidelberg SpeedMaster.

Image courtesy of Estrabols Imprimeur

The integrated prepress solution and MIS platform was added for a number of reasons, but Estrabol’s had some key objectives in mind. “We wanted to develop our offering for the high-end food markets, reduce our press lead times to less than 15 days and wanted to achieve a zero-defects quality standard,” says Marine Estrabols, managing director of Estrabols Imprimeur.

The optimization mission emphasized better tools for its employees to achieve lofty goals like a zero-defects quality standard and system solution approach.

The MIS platform is designed for the packaging and labeling segment and offers many platform modules tailored toward the label printing segment. The platform offers CRM, estimating, sales, products, production, warehouse and shipping to name a few. And the prepress platform adds the ability to automate quality checks and reduce errors.

With this integrated platform, brand owners can login and view existing or past projects while also being able to quickly calculate a price for a new project with different specifications. Customers can view each project with its technical characteristics like shape, size and the number of products within the project, along with paper quality, printing colors and project description.

Once a prepress operator receives a customer’s order, the MIS creates a job identification number, and all products and status changes will be communicated bi-directionally between the MIS platform and prepress software. During the prepress stage, an operator can define a label’s requirements, such as format and bleed, and the order will run through a number of checkpoints.

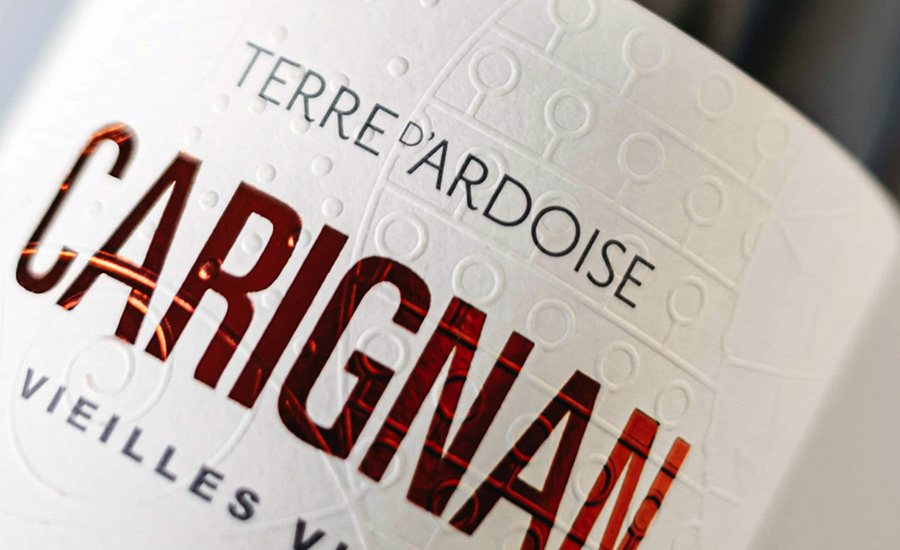

Image courtesy of Estrabols Imprimeur

From there, an operator can verify the file at every stage before generating a batch file. Once a batch file is created, an operator generates an email that can be sent to the customer for approval.

“The aim of the game is to enter your information once and the information will follow the workflow right along the production chain, so there are no duplicate errors, no risk of errors and saves time in terms of management,” says Pascal Guillorit, development manager at Estrabols Imprimeur.

Also, the robust automated capabilities help with converters and printers' biggest challenge right now: repeat jobs. Customers can repeat jobs at Estrabols Imprimeur and the prepress operators don’t have to re-enter a new order for customer service, prepress and print production. For example, the MIS system shares production process data and the prepress software automates the full step-and-repeat creation for each step in the print process.

This can even mean generating different plate types with customer marks and distortion applied when needed. “The fully automated step-and-repeat creation and automating repetitive prepress tasks such as report creation means that more time can be spent on value-added work,” says Guillorit. “At the prepress stage, reports are automatically generated, reducing errors and speeding up the job onboarding and approval.

While many companies are stretched thin due to customer demand and workforce issues, Estrabols Imprimeur's integrated system solution is accelerating the company’s growth and improving its standards of quality for its labels.

“We didn’t have an automated prepress system in place before Automation Engine,” says Guillorit. “When putting in the prepress software in place it made sense to do it right the first time, and connecting CERM allowed us to drive prepress with the same dataset used by CERM.”

Looks like these automated tools and the Internet of Things (IoT) is here to stay.