|

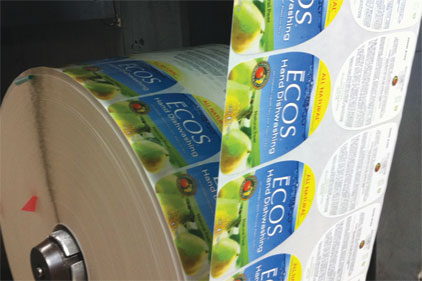

| Flexographic labels shown here from Earth Friendly Products’ Ecos Laundry Detergent are printed using water-based inks, lowering the V.O.C.s in the inks. Photo courtesy of American Non Stop Label Company |

Too much heat can also cause distortion of film substrates. Inks and substrates present their own set of challenges for the narrow web printer. Ink adhesion, gloss, product resistance, ink printability and ink migration are only a few of the concerns of the printer and the ink supplier.

Narrow Web Market Applications

Sales of flexographic printed flexible packaging, is expected to continue to increase with some estimates of global sales reaching $820 billion annually by 2016. The United States packaging market currently is around $150 billion with $27 billion of that share printed in the flexographic industry. With the expansion of flexographic printed flexible packaging have come many new and innovative products printed in both narrow and wide web formats.

The shrink film market in narrow web is one of the fastest expanding areas in narrow web flexible packaging, with the in-mold label market also increasing albeit at a much slower pace. The shrink film market is rapidly moving to flexographic printing through the increased quality in the processes and the rapid advancement of high-quality process printing capabilities in narrow web flexographic printing.

Innovations and Problem Solving in Printing

The evolution of flexographic printing has not ceased, nor slowed, in creating new opportunities for the narrow web printer. Equipment innovations borrowed from wide web presses make what was impossible to run in the past possible today within the ever changing narrow web market. Advancements in tension controls and servo-driven presses has nearly eliminated the issue of distortion of films in respect to web tension distortion and elongation, which has allowed the narrow web printer to print thinner and thinner gauge materials including both supported and non supported films.

Equipment drying systems utilizing higher CFM and less heat have improved drying and have also allowed for higher press speeds without contributing to past issues associated with film distortion due to heat. Use of cool UV systems and LED curing systems for UV inks has also contributed to the printer’s ability to print with less film distortion due to heat mitigation. Several press manufactures have and are introducing presses with chill roll or chill drum systems to also minimize any issues with film distortion due to heat generated by the improved drying and curing systems. Presses are also being manufactured with improved static control, web cleaning systems and idler rollers that have bearings that provide lower friction.

The new generation of servo-driven presses offer shorter web paths that have allowed for quicker set ups and reduced scrap. These presses coupled with automated registration and print impression settings also allow for quicker set ups and reduced scrap, thus increased productivity and the ability to further advance and increase the market share of flexible packaging in the narrow web market. There has been many improvements made for overall print quality in the narrow web market with advancements in pre press, plates, mounting tapes, and enclosed doctor blade systems for inks.

Ink chemistry has advanced significantly over the last few years due to the instability of the raw material supply chain and the lower profitability of the entire ink industry. With these difficulties came many challenges to improve product offerings, improve supply chain availability and the drive for improvement of the overall state of the ink industry.

Toyo Ink America has expanded research and development and has worked to improve partnerships with its global suppliers of all raw materials, while doing this many new opportunities for technical advancements have come from these relationships. Toyo has utilized its broad- based and diversified divisions of chemicals, colorants, adhesives, and our liquid and paste ink divisions to both compliment and advance the chemistry of the product offerings in the narrow web industry.

Ink Challenges and Solutions

While many challenges exist in printing flexible films in the narrow web format, many innovations used today have been borrowed from years of experience in wide web printing. These lessons learned have served both the narrow web printer and ink supplier dramatically in effectively producing flexible packaging products in the narrow web printed format.

Problems associated with adhesion on films, printability, gloss and dry speeds have been addressed for years in the wide web flexible film market. Ink systems now have enhanced adhesion properties whether the substrate is top coated, flame treated or corona treated, while also helping in areas with issues of plasticizers.

The problems associated with the use of high-slip packages in films and/or poor treat in the past have also been minimized. Wet out on a wider variety of substrates has required new and modified chemistry with both resins, and newly available surfactants utilized for both wetting out and leveling of the ink on film surfaces. Dry speeds on non porous substrates have improved significantly in water-based inks without increasing V.OC.’S, these improvements allow for the printer to increase line speeds without increasing V.O.C. in the ink chemistry.

The advancement of faster drying inks has also been coupled with inks that are more resoluble allowing for cleaner printing at a wider variety of press speeds without ink building up on the plates. The advancements of pigments and pigment availability, along with nonstop research and development of resin and pigment capabilities have increased the ability of the narrow web printer to print a wider variety of substrates and end-use applications in water base chemistry.

Energy curable ink chemistry has also advanced with faster cure speeds, extremely low plate swell, lower migration/non-migration applications, free radical chemistry, and catatonic ink systems. These systems are still the predominate ink systems used in the shrink film market as they offer good adhesion and excellent shrink properties at higher shrink percentages over conventional water-based ink chemistry.

Other Print Medias in Narrow Web Flexible Packaging

The digital press and equipment offerings have grown dramatically in both suppliers and technology. With these capabilities has come the ability to print many forms of flexible packaging in the digital format, some of the films being used are vinyl, PET, Lexan and BOPP.

With the addition of digital printing filling another gap in the arsenal of the narrow web printer of flexible film comes new opportunities to grow this market niche and both capture and augment the growth expected in flexible packaging well into the next decade and beyond.

Toyo Ink America, LLC

(201) 287-4000; www.toyoink.com