The move toward sustainable practices, products and materials is no longer on the horizon but ever-present. This is especially true as more consumers factor brands’ social responsibility initiatives in purchase decisions. In fact, global demand for sustainable packaging is expected to reach approximately $400 million by 2024 with a compound annual growth rate (CAGR) slightly above seven percent. As such, brands have begun to integrate environmentally-sound practices while other companies are leading the pack. Regardless of where companies currently stand on the sustainability spectrum, there is always room for growth—and certainly the demand to support it.

As consumer awareness of sustainable brand practices grows, there are some considerations that companies must make to catch up or stay ahead of the curve.

Educate Your Audience

Generally speaking, consumers are increasingly motivated to be more environmentally conscious. While consumers generally gravitate toward sustainable packaging options , they may not fully understand the impact they have on the sustainable supply chain and how to properly recycle or compost products after use. As such, brands should ensure that their audiences understand the role they play so that that they may better integrate sustainable practices in their daily regimen.

Currently, manufacturers are using labels to indicate the sustainability advantages of packaging choices and to provide instructions on how to recycle the material after consuming with the product. Additionally, brands can implement smart packaging such as Quick Response (QR) codes that enable consumers to access additional information on a product and are capable of educating end-users how to recycle it from a simple scan.

Brands that are making strides to be more environmentally conscious resonate more with consumers and influence purchase decisions. As such, it is in brands favor to communicate its efforts surrounding more sustainable practices in their operations.

Consider Materials from All Angles

While the adoption of sustainable materials is better for the environment, the use of certain substrates like those that are biodegradable, can tack on additional costs compared to traditional non-sustainable materials. Biodegradable packaging is qualified by the material’s ability to completely break down and decompose into natural elements within a short time after disposal, typically within a year or less. The materials used can consist of paper and cardboard, corn starch, recycled polythene or plastarch material (PSM). Moreover, brands are often met with challenges in sourcing sustainable materials to create quality packaging. As more consumers demand sustainable packaging and more manufacturers implement eco-conscious solutions, the supply of sustainable materials dwindles. This can affect the price of the overall product, which can consequently turn consumers away. However, consumers are more likely to pay more for a product knowing that it has sustainable qualities.

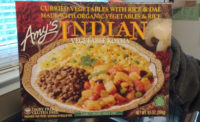

Certain packaging options preserve foods with minimal or no preservatives. Companies need to ensure that as natural and organic foods continue to grow in popularity, the packaging also has sustainability enhancing attributes like recyclability or biodegradability. These as well as reusability, resonate with audiences. Flexible packaging is an example of a format that has numerous sustainable benefits for manufacturers while offering consumers convenience for on-the-go consumption and reusability attributes to address food spoilage concerns.

Seek Innovative Materials and Solutions

When designing sustainable packaging, manufacturers should take note of the materials being used to ensure the quality aligns with the product and brand promise. Consideration of materials can enable a product to feel more premium than others. For example, packaging consisting of paper or cardboard can incorporate different forms of lamination and varnishes to give a more premium aesthetic and feel.

Manufacturers have also begun to design reusable containers to extend beyond a single use. Brands such as PepsiCo, Nestlé and Unilever have emerged with stainless steel and glass containers, double-walled steel containers as well as aluminum containers for refillable products like orange juice, oatmeal flakes, ice cream, deodorant sticks and refillable toothpaste tablets.

In addition, efforts in sustainability can also extend beyond packaging. For example, efficient use of ingredients, processing techniques that safely preserve food and operations that reduce energy consumption, waste and reduce emissions all contribute to enhancing a brand’s sustainability. For example, as consumers continue to gravitate toward products with fewer preservatives, High Pressure Processing (HPP) can address shorter life-span needs to compensate for a lack of chemical preservatives. HPP is a processing technique used to package organic and natural foods susceptible to spoilage with the application of purified cold water at incredibly high pressures. This technique enables brands to not only streamline production efficiency but also meet sustainability targets by utilizing renewable energy and recycled resources like water and electricity.

Sustainable solutions at PACK EXPO East 2020

Brands and OEMs need to ensure that they are keeping up with environmentally sound practices and maintaining their commitment to sustainability. Manufacturers can keep up with the industry trends, insights and technologies to implement the latest solutions by visiting PACK EXPO East (March 3-5, 2020, Philadelphia Convention Center). Owned and produced by PMMI, The Association of Processing and Packaging Technologies, the show offers attendees the opportunity to see the latest sustainable solutions for manufacturer’s operations from more than 400 exhibiting companies. The show will also offer educational programming and opportunities as well as feature up to 7,000 attendees to network with industry peers. Register and learn more at www.packexpoeast.com.

About PMMI

PMMI, The Association for Packaging and Processing Technologies, represents more than 850 North American manufacturers and suppliers of equipment, components and materials as well as providers of related equipment and services to the packaging and processing industry. Learn more at www.pmmi.org