Many prominent consumer packaged goods (CPG) companies have set ambitious sustainability objectives, like targeting a supply of high levels of recyclable or reusable packaging as soon as 2025, while reducing the use of plastics.

These goals resonate with consumers. According to a 2018 study conducted by the Flexible Packaging Association (FPA), 78% of consumers say that they support or buy from businesses with sustainability initiatives, and 79% say they prefer products that are in sustainable packaging over products that are not.

The key to helping CPGs meet their 2025 targets is cross-industry collaboration. Flexible packaging converter partners play a key role by working closely with their suppliers, such as ink, coating, adhesive, paper and film manufacturers, to develop packaging solutions that achieve greater sustainability.

Ink and coating manufacturers then must also work closely with their own suppliers, with regulatory bodies, with substrate and equipment manufacturers, and with material recovery facilities and recyclers through a wide range of industry consortia and trade organizations — such as Circular Economy for Flexible Packaging (CEFLEX), Food Packaging Institute (FPI), the Sustainable Packaging Coalition (SPC) and more — to develop an overarching approach to meet market demands and regulatory requirements.

Working with partner organizations across the overall supply and value chains to define common sustainability goals helps to prioritize initiatives, leading to more substantial and long-term solutions.

For example, many brands have followed the United Nations’ “2030 Agenda for Sustainable Development” by setting corresponding sustainability goals to achieve by the year 2030. Some partner companies, like Sun Chemical, are also aligning their goals with those on the UN’s agenda to ensure necessary actions are taken to enable a more sustainable packaging industry with an overall positive impact on the environment.

The collaborative approach allows ink and coating manufacturers to see the full circular economy requirements, allowing product designs that consider not only cradle to gate but also cradle to grave.

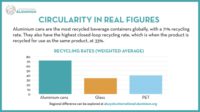

By working together to establish common goals and by utilizing renewable resources and raw materials that promote bio-renewability, compostability and/or recyclability, CPGs can help achieve the vision of a circular economy as introduced by the Ellen MacArthur Foundation. (Figure 1, page 32)

Recyclability

One example of partnership can be seen in the recycling of polyethylene terephthalate (PET) bottles. Heavily driven by CPGs and brand sustainability goals, due to their recyclability, roll-fed labels specifically on PET bottles have already seen an increase in widespread adoption.

By working with the Association of Plastic Recyclers (APR) and teaming up with its diverse members, an ink or coating manufacturer can help to explore ways to further boost the rate of PET recycling and ultimately assist CPGs in achieving ambitious sustainability goals around improved PET bottle recyclability.

This collaboration has resulted in enhancements to a current ink offering with a recycle-friendly new washable ink technology for the flexo market currently in development. This ink technology can be removed from post-consumer printed PET packaging in typical existing recycling processes, without staining the recovered PET flake or the process wash water. Designed for crystallizable PET shrink sleeves that can be recycled together with the PET bottles, the washable ink allows for the increased recovery of high-quality, clean, recycled PET resin.

Bio-Renewability

Brands are also prioritizing sustainability through the use of bio-renewable inks and coatings. Utilizing printing products that are derived from renewable materials such as plants, rather than from petroleum-based sources, lowers the overall CO2 footprint of a package.

The fast food market has taken a strong leadership position in adopting bio-renewable inks and coatings. By printing bio-renewable inks for paper packaging on substrates such as paper bags, wraps, clamshells and paperboard, food service CPG companies are reaching their sustainability goals.

Collaboration was an important element in developing bio-renewable inks that meet the printing and application performance requirements for the converters while also being sustainable to meet the objectives of the CPGs and their consumer customers.

It is important that bio-renewable contents are verified by a third-party lab to ensure consistent reporting and accuracy in claims. For example, the National Association of Printing Inks Manufacturers (NAPIM) offers a universal verification program to the printing ink industry which calculates and reports the bio-renewable carbon (BRC) content of any ink through a BRC index number.

Compostability

Compostable packaging is another route that many brands are exploring to improve sustainability because this option allows brands to still achieve their sustainability goals without sacrificing flexibility or the number of product iterations. It also requires collaboration between converters, ink manufacturers and substrate manufacturers to ensure the full package can be certified as compostable.

For a package to be compostable, all aspects of the package — inks, coatings, adhesives, substrates — must also be compostable. Each one of its components must biodegrade naturally within a specified timeframe under controlled conditions or be confirmed not to negatively impact that biodegradation. The design of the package and application of various components must comply with specific standards.

To ensure that the inks conform to the compostability standards, companies rely on certifications provided by independent entities, such as TÜV Austria in Europe and BPI in North America, that carry out laboratory tests on the finished packaging product or on its separate components (including the inks) to prove that they fully meet European EN 13432 or North American ASTM D6400 and D6868 protocols.

If certified, the material used would be considered compostable or compliant with compostability without leaving excessive levels of toxins, heavy metals or plastic residues in the soil.

Ink manufacturers that also manufacture compostable adhesives and coatings can produce a variety of solutions that work together as one in a compostable package — a one-stop shop that could greatly benefit CPGs in reaching their sustainability objectives.

The Circular Economy

When it comes to achieving overall packaging sustainability and circularity, many organizations across the total supply chain must come together to deliver different components to meet the larger objective.

The CPGs are driving the need to consider the full lifecycle of any packaging or printing product beyond its use in the application to its end of life and disposal.

By aligning goals toward a common outcome, working with partners and associations that hold similar sustainability values, and by prioritizing a sustainable end result for all products released into the market, the packaging industry can reduce greenhouse gas emissions, minimize waste production and, one day, truly achieve sustainability.