The products below will be show at PACK EXPO Connects in Virtual Showrooms:

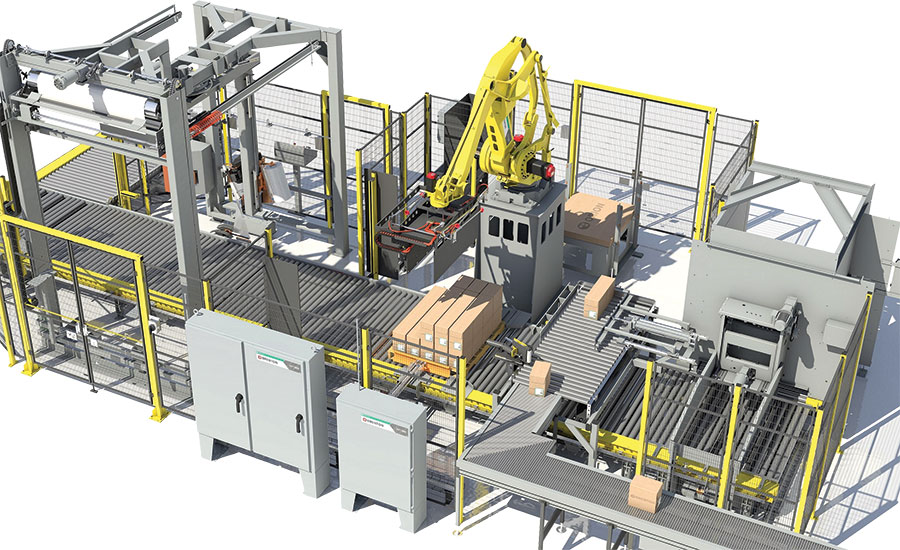

Brenton Showcases End-of-Line and Robotic Integration

Brenton, a ProMach brand, will be showcasing its end-of-line packaging and robotic integration in case packaging, palletizing and material handling with 12 virtual demos throughout the event. End-of-line packaging using robotic pick-and-place is gaining acceptance as the go-to packaging system for the pharmaceutical and medical device industries. Robotic pick-and-place offers a more compact, efficient design; it brings a higher level of cleanliness to end-of-line applications; and it has a proven track record of reliability, durability and accuracy. Integrating robotics into palletizing is an efficient option for carrying hard-to-handle products, as well as larger scale systems with an optimized footprint. Brenton offers various options when it comes to picking the right robotic packaging equipment for a client’s exact application. One of many things that sets Brenton apart from competing companies is its drive to work closely with customers to develop new technologies. Many of the company’s virtual demonstrations during PACK EXPO Connects 2020 focus on new technologies Brenton has developed for the packaging industries. Visit Brenton’s Virtual Showroom for its demo schedule.

Reduce Guide Rail Changeover with Easy Adjustable Rails

Septimatech, a provider of packaging machine and line productivity solutions, offers Easy Adjust Rails, a low-cost/high-value economical solution with a quick ROI and a low total cost of ownership. Conveyor guide rail changeovers are repeatable, fast and easy. The small footprint, lightweight guide rails are not only economical, they are also sustainable with no compressed air resources. The rails are maintenance free, with no seals, springs, wires or supply lines subject to wear, damage or leakage. They also offer a one-time calibration of the system. Easy Adjust Rails also are engineered to retrofit to any existing or new conveyor systems, interchangeable when line configuration needs to change. Install Septimatech Easy Adjust Rails on a new or existing conveyor to improve changeover efficiency and create greater line flexibility to infinitely adjust guide rails for current and future product introductions. Visit Septimatech’s Virtual Showroom for its demo schedule.

BW Packaging Systems to Unveil Various Solutions

BW Packaging Systems has more than a few innovations being showcased at the event. Just to name a few:

- Accraply Trine Modular Labeling Station: Designed to bring next-generation roll fed technology to existing Trine systems, this upgrade includes the latest technology in glue roller and cutter designs. This will reduce operational and maintenance costs and increase uptime and throughput.

- BW Flexible Systems Hayssen ISB High-Speed Continuous Motion VFFS: The ISB’s new innovative sanitary design is suitable for the most demanding applications and challenging environments. Discover the benefits of this vertical form fill seal bagger and explore the machine’s outstanding HMI and UX features.

- BW Integrated Systems Maximus Mid-Speed Palletizer: The Maximus Mid-Speed Palletizer was designed specifically for the 30-70 case-per-minute palletizing market. This machine features a smaller footprint and is 100% electric, making it more reliable and less expensive to operate.

See these machines in the BW Packaging Systems virtual showroom.

New Edge Roller Technology Conveyor Highlights Dorner’s Showroom

Dorner’s new Edge Roller Technology (ERT250) conveyor will be the highlight for the company’s virtual showroom. The ERT250 is a pallet handling conveyor capable of zoning for accumulation and automation assembly applications. As implied by its name, the ERT250 uses rollers to move pallet conveyors smoothly with no friction (a byproduct often seen in belt-driven platforms). The rollers are driven by a patent-pending, energy-efficient linear gearbox that offers added flexibility with motor positioning and zoning. This allows for zone and slip roller operation. Simply removing a lower gear creates independent zones. The non-contact zone control provides simplified traffic control that eliminates pallet stops and costly pneumatic valves. Conversely, slip rollers can be used for full-length runs with conventional pneumatic pallet stops. The rollers are easily accessible and can be replaced quickly without affecting the remaining portion of the conveyor. The ERT250 is ideal for applications calling for pallet or tray handling; no- and low-back pressure accumulation; medium to heavy load assembly automation; and cleanroom applications such as medical product or device manufacturing, assembly and packaging. Visit Dorner’s virtual showroom.

METTLER TOLEDO’s CI-Vision V15 Round Line Smart Camera System for Wet Environments

The CI-Vision V15 Round Line smart camera inspection system from METTLER TOLEDO is designed to confirm the presence, completeness and readability of alphanumeric label information and printed 1D and 2D codes on round packaging. It also rejects packages not in compliance. Target containers include food jars, cosmetic containers and household chemical containers. Using six evenly distributed viewpoints and liquid lens focusing technology, the V15 conducts 360-degree container inspection to ensure that both label ingredient information and inkjet-printed codes are clearly readable. The liquid lenses adjust automatically to the distance from the target, enabling the system to inspect containers of different sizes without physically moving the cameras. Optional cameras can be added to the system to inspect the tops and bottoms of containers, where additional codes are often placed. The entire system is housed in a stainless steel cabinet, keeping it secure even in harsh washdown environments. Visit Mettler Toledo’s showroom.

Matrix Highlights Form Fill Seal Baggers, Pre-made Pouch and Stickpack Machinery

Matrix, a ProMach brand, will be hosting a total of eight virtual demonstrations on its lineup of vertical form-fill-seal baggers, pre-made pouch and stickpack machinery during the event. Manufacturing these gel and freezer packs is a task suited for the Matrix Mercury vertical form-fill-seal machine. Mercury is a high-speed VFFS bagger that can fill up to 140 flexible packaging bags per minute. The Mercury is known for its easy operation and quick changeover and setup. It can accommodate bag widths between 2 in. and 11 in., and bag lengths between 3 in. and 15 in. The Mercury features a small footprint, stainless-steel frame, automatic film tracking, a registered film sensor and more. For customers who require more hygienic attributes in their filling machine, the Matrix Elete Premier is a vertical form-fill-seal bagger that is a high-performance, totally configurable packaging solution features a stainless-steel, sanitary design. All major components, including fasteners, bearings, shafts and motors are suitable for washdown environments. The flexible Elete Premier can produce several different bag sizes, such as pillow, gusset, quad and flat bottom with a variety of films, including 100% recyclable, at filling rates up to 120 bags per minute. Visit Matrix’s virtual showroom.