A benefit of technology is it gives us the ability to use our time more wisely and the means to do so. Saving time by automating your purchases could mean scheduling your cat food to get delivered to your doorstep every two weeks, or picking out new makeup without leaving the house. Online, we have unlimited access to products and services we might not have or even known about in person. And while we were shifting toward contactless delivery before 2020, the COVID-19 pandemic has prompted us more than ever to incorporate e-commerce and technology into our lives. With this advancement inevitably comes the very real threat of counterfeiting.

While counterfeiting has always challenged brands, with e-commerce taking the lead, consumers are bombarded with the possibility of being affected. Governments across the globe are trying to implement strict legislations and penalties and encourage brands to use anti-counterfeit packaging, but the markets continue to be flooded with undetectable fakes. The World Customs Organization reports that counterfeit goods bring in over $650 billion every year.

Video courtesy of Applied DNA Sciences, Inc.

Counterfeiters can cause damage and pose serious safety concerns for everyone involved. Manufacturers are incorporating the following sophisticated technology into packaging to get ahead of the counterfeit industry:

- Radio frequency identification tags (RFIDs) equipped with microchips

- Security Seals

- Barcodes

- Security Ink & Printing

- Smart Labels and Holograms

- Mass Encoding

- Digital Encryption & Serialization

TRENDS IN ANTI-COUNTERFEITING

An analysis from Research and Markets on the anti-counterfeit packaging technologies market estimates it will reach $420.97 billion by 2028. RFID technology is projected to have the fastest growth during the forecast period which features supply chain tracking, high security against duplication, wireless identification and distant tag reading. Coding & Printing offers low cost, easy application, recognition and technology incorporation, and is expected to dominate the market.

Innovations in detection technologies come with investment costs that can deter small and medium manufacturers from protecting themselves; however, reasonable solutions are available. SnapDragon is one company offering brands its affordable Swoop technology, capable of detecting counterfeit products in real-time and removing the links across online platforms.

Applied DNA Sciences, Inc. invented “Encrypted Optical Markers for Security Applications,” relating to its Beacon encrypted optical molecular marker technologies, that offers rapid, secure, real-time in-field authentication of a DNA-tagged substrate through an encrypted fluorescing signal when paired with a decryptant — otherwise making both Beacon and its SigNature DNA invisible to normal and UV light. The company also offers SigNature molecular ink for tagging, testing and tracking products and packaging along the supply chain.

Courtesy of Toppan Printing

As the digital world progresses, interactive customer engagement via smartphones is opening up brands to direct-to-consumer marketing that can take on counterfeiting. For its aftermarket parts packaging labels, Hitachi Construction Machinery Co., Ltd. adopted Toppan Printing’s ID-NEX — a cloud-based service with smartphone authentication utilizing the S-White hologram — which facilitates authentication and traceability using QR codes scanned with smartphones.

“Using Toppan’s ID-NEX authentication and traceability service will enable our customers throughout the world to confirm the authenticity of the parts we supply and use them with greater reassurance and peace of mind. We also aim to leverage enhanced traceability and distribution efficiency for parts to further expand value chain business in the future,” says Kenji Iitsuka, general manager, parts planning department, spare parts division, life cycle support group at Hitachi Construction Machinery.

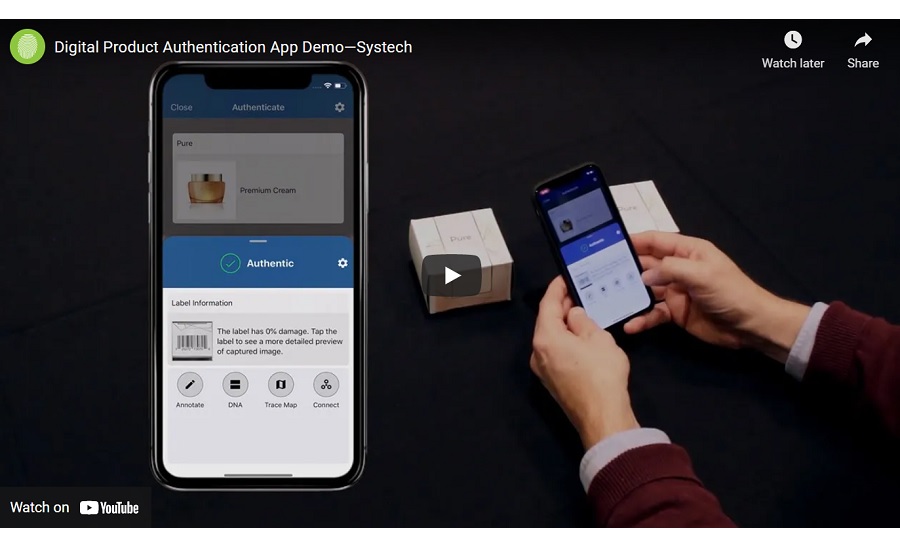

Systech, a solutions division of Markem-Imaje, offers UniSecure — authentication that works with existing barcodes and packaging. The company also released a white paper exploring how connected packaging can address protection, engagement and traceability in the industry.

Video courtesy of Systech

WINE PACKAGING

Wine fraud is becoming prevalent, with consumers having no way to tell if the wine they purchase is genuine. Eltronis, a specialist security printer, designed an irremovable holographic label that combines brand design with high-level security, including a unique, unreproducible code and serial number that enables verification online and via smartphones.

Pete Smallwood, business development manager for Eltronis, says, “We are increasingly seeing brands across many different sectors look at labels as a means to validate and protect their goods. Effective protection and authentication build confidence in a brand and enable it to stand out from the competition.”

The National Office of Vine and Vitivinicultural Products (ONVPV) in Romania used these labels to convey brand information and protect drinkers from potential counterfeits. Consumers scan the QR code uniquely linked to each bottle of wine to access information on the wine’s pedigree and production, confirming that it is genuine.

“With our latest label design, consumers can interact much more easily via their smartphones, giving them access to the latest information on their wines. This has proved very popular and already led to the annual volume used by winemakers more than doubling — and we expect this upward trend to continue,” says Dorin Ştefan DUŞA, general manager at ONVPV.

Courtesy of Eltronis

COSMETICS PACKAGING

At the end of 2019, Netflix released the documentary series Broken. An episode called “Makeup Mayhem” explored aspects of the underground world of counterfeit makeup manufacturing, drawing attention to the subject so consumers can hopefully catch on faster to counterfeit products and packaging. High instances of cosmetics fraud is confronting companies and manufacturers, but they are also inadvertently reinforcing the anti-counterfeit cosmetic packaging market. According to an analysis from FMI, the market is estimated to reach $50 billion with an 8.9% CAGR by 2027, and over 100 billion units of skincare anti-counterfeit packaging products will be sold by 2027.

E-commerce has experienced more demand for vulnerable cosmetic and hygiene products due to the pandemic, heightening the need for secure packaging. Tamper Technologies, a manufacturer of security labels and tape products, reported that counterfeit products seized in the U.S. contained dangerous substances and bacteria, presenting very serious health concerns for consumers. Future Market Insights reported the U.S. Customs and Border Protection seized over 2,000 shipments of counterfeit cosmetics worth $1.4 billion in 2015. “Packaging is the first and last line of defense for the consumer, as the counterfeiters are improving their product replication of boxes and bottles,” says Harriet Chiles, GM, Tamper Technologies.

While the growing trend of consumer interaction with packaging can communicate brand information and promotions, more brands need to invest in secure packaging technologies that can protect consumers — and themselves — from counterfeiters.