The development and gradual commercialization of NFC-enabled (Near Field Communication) products show how companies such as Thin Film Electronics (Thinfilm) are pushing the integration of electronic intelligence into everyday products, like packaging labels.

|

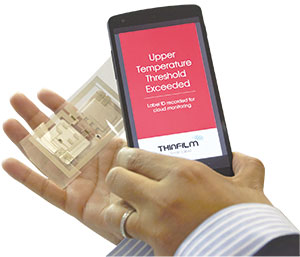

The Thinfilm NFC-enabled smart label detects that a critical temperature threshold has been exceeded, and an NFC-enabled smartphone wirelessly detects the signal then displays a corresponding alert on the device’s screen. |

Earlier this year, the Oslo, Norway-based printed electronics company successfully demonstrated the first NFC-enabled printed smart label technology, a system that incorporates printed-electronic labels with NFC and real-time temperature sensing to enable wireless communication and data exchange.

Matt Bright, director of technical marketing at Thinfilm, says he believes the flexible packaging industry is the next wave emerging on the horizon of NFC-enabled technology.

“I think this has to be a very exciting technology for the flexible packaging industry in general, because it’s an opportunity for the industry to realize that they have the capability to participate in the Internet of Things,” says Bright. “And that’s probably a position that flexible packaging companies have not been in previously – where they have a big role to play in the next generation of the network world.”

The ‘Internet of Things’ involves the integration of electronic intelligence into everyday items, enabling them to become interactive in a way that improves the consumer experience, as well as the ability of brands and retailers to interact directly with consumers.

That’s where Thinfilm’s NFC product offerings come into play.

NFC Barcode & Smart-

Label Applications

“So the NFC product portfolio for Thinfilm has two major product families. The first is called the NFC barcode, and the NFC barcode is an integrated circuit based on printed electronics that is applied to a flexible antenna – generally based on a plastic film – and that allows for the unique identification of any product, simply by being integrated into the packaging,” explains Bright. “Typically, it’ll be integrated using a pressure-sensitive adhesive label. But the exciting thing with the NFC barcode – which, by itself, opens up a whole range of applications for consumer interactivity and also business-to-business-use cases – is when we add sensors to the NFC barcode. Then we create what we call NFC smart labels.”

NFC smart labels are designed with the ability to monitor and report temperatures in real time, and can therefore be used for temperature-sensitive shipments of products like vaccines or perishables.

“By having access to an NFC barcode or an NFC smart label that’s integrated into the product packaging, not only do flexible packaging manufacturers enable business-to-business-use cases – like tracking and logistics, freshness monitoring for vaccines and other pharmaceuticals, and perishables – but they also enable business-to-consumer-use cases,” adds Bright.

Both the barcode and the label have a unique identification number inside, which allows for that individual package to be interactive with the consumer. And from a supply-chain-management perspective, Bright says this feature gives manufacturers the ultimate resolution down to the specific item.

Cost and Integration

“Some of the more sophisticated smart labels that might be able to detect multiple temperature thresholds and have wireless communications capability could be a couple of dollars,” explains Bright. “So like many things, there’s a range of functionality and opportunity; but when it comes to that range, there’s a lot of flexibility and opportunity for innovation at different price points.”

NFC barcodes and smart labels are built onto flexible substrates, which are then integrated into a flexible, pressure-sensitive adhesive label. This label can then be applied to flexible packages as they move along the production process. Whether it is actually applied to the rollstock or the actual package is left to the discretion of the manufacturer; it simply depends on the package type and how it’s manufactured.

The Next Wave

Bright explains how the flexible packaging industry has the opportunity to become a part of the next phase of NFC technology.

“There are examples of NFCs being deployed into applications such as retail point-of-sale displays, but NFC moving into the individual package level is something that’s the next wave (and) that’s essentially emerging on the horizon,” says Bright. “So that’s where the industry is in the process of shifting from the mode where NFC tags were used maybe one per shelf display, for example, within a retail environment, and a consumer could touch their NFC phone and get access to interactive content at the shelf level, in-store. But having access to actually bring that NFC tag home with them as part of the package, that’s what is the next wave that’s coming just over the horizon. And that’s where the flexible packaging industry really has the opportunity to participate.”

Thin Film Electronics ASA

(408) 503-7300

www.thinfilm.no