Prior to the enactment of the Poison Prevention Packaging Act (PPPA), pediatricians widely considered poisoning by common household substances to be the leading cause of injuries for children under 5 years old. Child-resistant packaging technology has been enormously effective in reducing the frequency and severity of incidences involving the ingestion of hazardous substances among young children. Until recently, however, no flexible packaging application was capable of meeting current regulations for child-resistant reclosable packaging. A flexible packaging solution that met the criteria established by the PPPA would allow for a wide variety of product segments to convert from rigid containers to flexible for the first time, in turn enjoying the unique benefits that are characteristic of flexible packaging.

History of Child-Resistant Packaging

The proliferation of household chemicals following World War II put children at an increasingly greater risk of ingesting poisonous materials in the home. A growing level of concern about the problem culminated in the passage of the PPPA by Congress in 1970. The law was designed to prevent children from unintentionally ingesting hazardous household substances by mandating that certain products – such as chemical products, cosmetics, mouthwash, drugs and dietary supplements – be kept in “special packaging.” The PPPA defines special packaging as “packaging that is designed or constructed to be significantly difficult for children under 5 years of age to open or obtain a toxic or harmful amount of the substance contained therein within a reasonable time and not difficult for normal adults to use properly, but does not mean packaging which all such children cannot open or obtain a toxic or harmful amount within a reasonable time.”

In order to ensure that a package met these stipulations, the Consumer Product Safety Commission (CPSC) – which retains the authority to regulate the PPPA – implemented a testing protocol in which children between the ages of 42 and 51 months old are given the package in question and instructed to attempt to open it. A child is initially given five minutes to open the package. At the end of this allotted time, he or she is provided with specific instructions as to how to open the package, and is given another five minutes to do so. If a child opens the package during either section of the test, the package is considered to have failed in that instance. In order to be deemed child-resistant, the design must have prevented 85 percent of children from opening the package during the first five minutes and 80 percent during the latter five minutes.

A Flexible Option

Historically, child-resistant packaging has been limited to rigid containers. Rigid options were the only type of packaging capable of meeting the rigorous testing protocol set by the CPSC. For companies in the flexible packaging space, creating a child-resistant option became a coveted goal. Over the last several years, flexible packaging companies have worked on a number of potential solutions, most of which centered on creating different types of press-to-close options. Those that were created, such as a press-to-close technology with a hidden zipper, served only to increase the difficultly of opening a package while not resulting in truly child-resistant packaging.

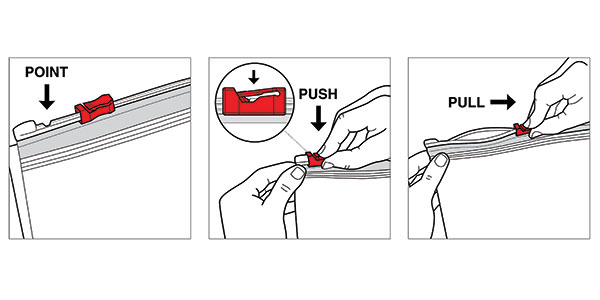

In order to develop a flexible packaging technology that was able to carry the distinction of child resistance, the engineering and R&D teams at Presto Products Company developed a solution that would effectively protect children in the household. After two years of working in conjunction with a major Consumer Product Goods (CPG) partner, Presto launched a new type of closer. The closure, named Child-Guard, is an enhanced version of a slider that is extremely difficult for a child to open, yet is simple enough for adults and seniors to open easily. Child-Guard became the first child-resistant slider available for application on pouch packaging that meets Title 16 CFR 1700 of the PPPA. The technology also holds ASTM D3475 classification from ASTM International, a similarly rigorous standard for child-resistant packaging.

The Best of Both Worlds

Flexible packaging is lighter in weight and more compact than rigid alternatives, decreasing the cost of transportation throughout the entire supply chain and improving sustainability efforts. Brand owners can now take full advantage of these benefits for a number of product categories in which regulations mandate child-resistance for reclosable packaging – including home care, chemical, pharmaceutical, nutraceutical and any other granules, powders and solid mixes that should not be consumed by children or taken without adult supervision. Other developing markets, such as medical marijuana food products that require child-resistant packaging and would benefit from the high-barrier protection offered by flexible packaging to retain freshness, are also well suited for this application.

Presto Products Company

(800) 265-0750

www.fresh-lock.com

"Poison Prevention Packaging." United States Consumer Product Safety Commission. 1 Jan. 2005. Web. 20 Mar. 2015.

"POISON PREVENTION PACKAGING ACT." United States Consumer Product Safety Commission. 30 Dec. 1970. Web. 20 Mar. 2015.