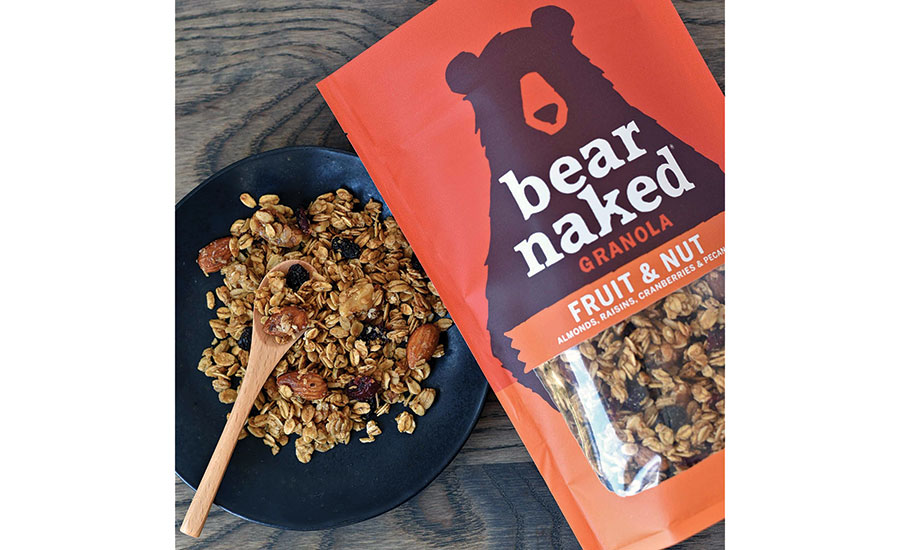

It was about three years ago when Bear Naked Granola decided it wanted to overhaul the packaging on its line of best-selling granolas and granola bites. As a leading brand in the granola space, it wanted to take the lead in another important category: sustainable packaging. But the brand wanted to maintain the feel, function and appearance of its current packaging.

After all, more than 135 million bags of granola are sold per year. The Bear Naked team says it felt obligated to create a future less reliant on single-use plastics, where it could make a meaningful impact. As it turns out, Bear Naked’s circular economy goals were in harmony with that of Berry Global’s, so the two partners — and others — set out to create truly recyclable packaging.

The project required 18 months of focused development by each partner to deliver a fully functional package. Key challenges included modifying the film to improve efficiencies on high-speed HFFS packaging machines. In addition, the team worked to optimize line conditions to function effectively with the film, zipper and ink systems to create the standup pouch. The new recyclable package has enhanced barrier properties compared to the incumbent package, resulting in better retention of freshness and flavors.

Here’s a closer look at the partners and various roles they each played in the development of Bear Naked’s new packaging line:

Berry Global (www.berryglobal.com): Its 9-layer blown extrusion equipment and key material knowledge created its Entour film structure for the package, which surpassed the barrier requirements, enhancing shelf life. The film provides a window with good clarity to showcase the product, excellent stiffness to stand tall on the shelf, and superior sealing for hermetic packaging that require gas flushing. These benefits, paired with the ability to recycle the pouch, have proven to be a good fit for the Bear Naked brand. Like any other single-source polyethylene films, this film is accepted at front-of-store collection.

Colormasters (www.colormastersllc.com): The company provided high quality print capability for outstanding graphic appeal with a registered matte finish to the package, reinforcing the brand image. The matte finish also provides extra heat resistance, allowing the package to run more effectively on packaging equipment.

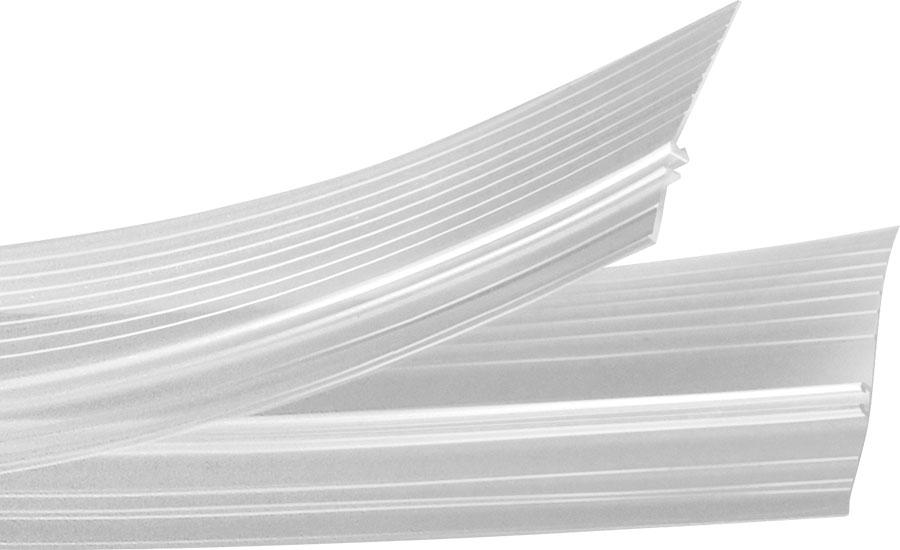

Fresh-Lock (www.fresh-lock.com): It developed the 8000 Series, a new recycle-ready line of zippers, and worked to ensure the closure was compatible with the film sealing system while still delivering the ideal consumer experience for reclosable pouches. The zipper enabled faster packaging machine speeds and consistent sealing preventing channel leakers, which enabled the granola to stay fresh use after use.

Dow Chemical (www.Dow.com): Dow’s RecycleReady Technology enables recyclable film structures that have been approved by the Sustainable Packaging Coalition for the How2Recycle Store Drop Off Logo. Dow’s RETAIN Functional Polymer Modifiers compatibilize a barrier resin with polyethylene, enabling a recyclable film. This innovative compatibilizer technology allows for front-of-store recycling of flexible barrier films. Dow also provided high performance sealant for the standup pouch to meet demanding packaging machine speeds and providing hermetic packages.

“We created a new sustainable package but maintained the feel and functionality of the current package so consumers will continue to find the product they expect in a package with a striking appearance, solid product protection and reclosability for multiple uses,” notes Paul Wolak, senior technical director, Berry Global. “The key difference is that consumers can feel good about helping the environment by returning the package to the store, which eliminates waste and creates extended use. Through the advanced material science in plastic packaging, we have the unique opportunity to enhance sustainability, without negatively impacting the consumer experience.”

Building sustainability into package design requires the collaboration of all contributors. Every supplier on this team was aligned to the common goal of creating a new package with secondary life as an outcome. The model of a circular economy requires the elimination of waste be part of the initial design. The united, cross-functional collaboration allowed all influencers to experience the impact of partnership in design resulting in a package that works making this project truly special.

Bear Naked’s new line of packaging is set to ship to stores in mid-2019.

.jpg?height=200&t=1652126480&width=200)