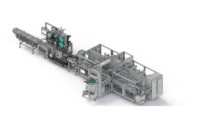

Mespack, a leading manufacturer of innovative and sustainable flexible packaging solutions, is launching the new MCP series for secondary packaging. This series, comprised of automatic American box machines, is integrated with a robotic picking system.

Mespack offers integrated solutions for end-of-line production requirements. From cans, bottles, capsules, and solid products to flexible packaging, the company’s end-of-line solutions have the ability to operate with various secondary packaging formats.

Secondary packaging is instrumental in regard to the diverse facets of a product; the most important are product protection and primary packaging during transportation. Other important aspects include those in reference to display, distribution, and branding. Concerning the availability of Mespack’s secondary packaging solutions, the focus is on those which are the most sustainable, particularly cardboard based solutions.

In reference to American box solutions, the MCP series is regarded as the new secondary packaging picking equipment that can provide turnkey projects for the RSC market. This state of the art machine is not only highly technological, but also includes devices such as delta robots and servos. As a result of its versatility, and in order to increase production speed, up to 4 four picking modules are available. This new MCP series offers numerous features:

- An Acceleration Belt (optional): This belt accelerates to change the distance between two pouches from the previous station in order to be adapted to the picking speed.

- A Vision System: This 3D vision system is integrated into the machine entry and detects the pouch position in order to transfer it to the picking robot.

- A Picking System: The delta robot is used to pick pouches and horizontally place them inside of American box.

- An Automatic Changeover Belt: This belt is able to perform an American box format changeover through HMI in less than 30 seconds, as a result of its full servo characteristic.

- Flap Control Guides: These guides are keeping flaps permanently open.

“From our project department at Mespack, we realize that customers increasingly value turnkey solutions, allowing them to focus on their core business and have one single interlocutor that facilitates the entire processes of both primary and secondary packaging,” said Solutions and Projects Director Jaume Roquet.

Similar to the whole Mespack product range, this series is governed by the Athena control platform as well, enabling us to ensure a perfect functional integration with primary packaging machines. The Athena platform allows Mespack to successfully offer turnkey projects.

The MCP family has been added to our repertoire of secondary packaging solutions, which includes series such as the W and EF. Consequently, the end result is an extremely complete range for the end of line.

To have only one partner for primary and secondary packaging solutions has several benefits for the clients, including:

- One unique responsible supplier

- Profound knowledge of flexible primary packaging

- Complete project vision and control (from primary packaging to secondary and EoL)

- High efficiency of the entire line

- Accurate layout of the full line

- The bulk of a line in the same place

- Cost reduction for the customer

Mespack has the largest product portfolio of the industry, which offers horizontal (including roll-stock, pre-made, and hybrid), vertical, and water-soluble pods equipment for the production of sachets, stick packs, stand-up pouches, film-based packaging, and end-of-line solutions.

To learn more about Mespack, please visit https://mespack.com/.

.jpg?height=200&t=1652126480&width=200)