Innovia Films, the global manufacturer of specialty BOPP packaging and labeling solutions with performance coated films, tobacco overwrap, graphic media, label, and security film, is a forerunner in sustainable graphic arts films. The company, which already produces PVC-free film for wide format (digital) printing, is set to become part of the solution in fostering circularity in this segment by broadening its sustainable graphic arts film potential. To implement its vision, Innovia Films has committed to a major investment and partnered up with BOBST in this project to produce a brand-new range of PVC-free films.

The BOBST coating line, customized to Innovia’s specifications, will be installed at their site in Wigton, UK. Full production is expected to start early in 2025.

Expertise is key in finding the right technology to drive sustainability and productivity

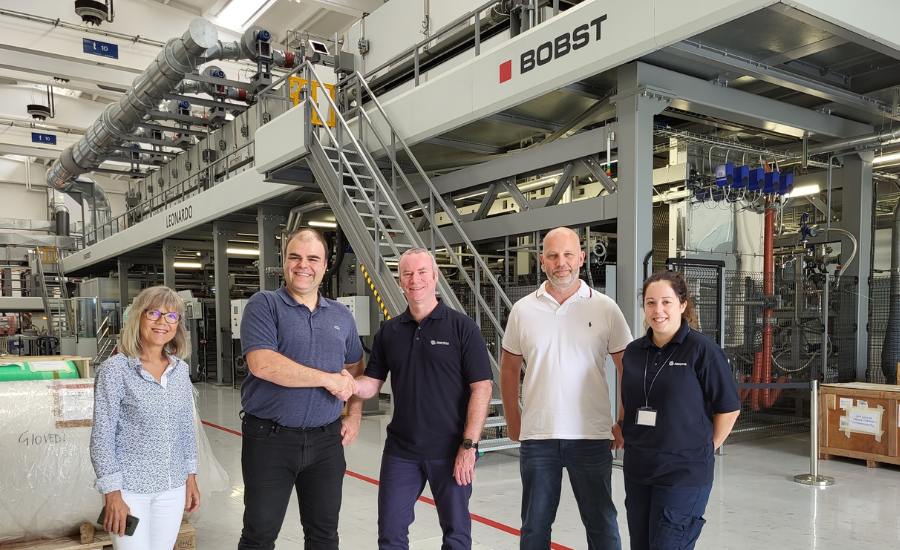

For two years Innovia’s technical team worked very closely with BOBST at Bobst Italia’s Competence Center in San Giorgio Monferrato, Italy, to specify the design of their new coating line. Central to the project development, and to Innovia’s choice of partnering with BOBST, were the capabilities of the BOBST LEONARDO pilot coating line which was used for the R&D trial and tests.

“Our new PVC-free product range was developed internally but we had to find the right equipment and technology to be able to industrialize it and deliver upon our stringent requirements and specifications. We supplied the substrate, the coating material, and the product we wanted to achieve for BOBST to design a machine that could manufacture these new materials with the required quality, efficiency and profitability,” explained Steven Maude, Surface Engineering Manager at Innovia Films, who is responsible for the project at the Wigton site.

Different iterations of tests were carried out that would determine the design specifications. It was necessary to find out the right coating system and the corresponding drying capability which would dictate the size of the coating machine to be built. All of course not only in terms of the high quality of the material but also the economic viability of the project: machine speed, manufactured tonnage of material and payback of the investment.

Tests were carried out at both BOBST and Innovia’s in-house laboratories on the coating quality, grammage, gloss, etc., as the new PVC-free products must provide the durability and the required printability for commercial applications. The coated reels were tested for printability at Innovia’s R&D Centre in Wigton, UK, on wide-web digital printers covering the print techniques commonly used in graphics arts applications – ecosolvent, UV and latex.

Other than the trials relating to the process and equipment features in terms of the output quality, BOBST had to also deliver on Innovia’s requirement of a coating machine capable of offering flexibility of web widths and changeover speed to enable the company to make width-to-order production runs and to minimize waste of material and downtime.

“These are high value products so smaller batch sizes with fast changeover speed is paramount,” continued Maude. “We were able to time the sleeve changes on the LEONARDO, as if in a real production environment. This takes only minutes, and the trolley features we specified will enable us to carry out pre-changeover work when the machine is running, again helping with changeover speed which is key.”

“This project was quite challenging, which made it even more exciting in a way,” commented Alexandre David. “But we had the confidence of knowing that we are standing on a sound ground on the strength of the capabilities of LEONARDO that enables trials on wide-web production scale equipment.”

The impressive 40-meter long BOBST pilot line offers multiple coating systems that work with over 30 coating methods, as well as 4 different web-handling and drying technology systems. Up to 1350 mm in web width it has a mechanical speed up to 1000 m/min.

Innovia and BOBST: ready to provide a new competitive edge for their customers making the move to circularity

When developing alternatives to existing solutions, brands and converters must ensure that they are able to properly assess the quality of any new material and the economic viability of the industrialization process. The outcome of this project is an example of a very successful collaboration towards this end. The new wider range of PVC-free high quality graphics applications will offer more brands and retailers the option to reduce the environmental impact of their wide format printing products.

“There is no doubt that a change is needed in this segment of the graphic arts industry to make it more sustainable and in the end – recyclable,” explained Maude. “So there is a requirement for change but to further motivate the market to move towards alternatives to PVC, these must offer similar performance characteristics, be economically viable, and be suitable for the required applications.”

“The way we look at circularity in packaging now, at one point it will become a requirement everywhere in the search to replace harmful production processes and enable recyclability at the end of life of a product. And PVC-free graphics arts are a great alternative.”

.png?height=200&t=1656523554&width=200)