The world market for packaging machinery value is expected to reach $42.2 billion by 2021, according to PMMI’s “Global Trends Impacting the Market for Packaging Machinery 2018” report. As the market becomes increasingly larger and more complex, PMMI presents PACK EXPO International and the co-located Healthcare Packaging EXPO taking place October 14–17, 2018 at McCormick Place in Chicago.

PACK EXPO International will address the trends and challenges driving the food and beverage, pharmaceutical and medical device, cosmetics and personal care, industrial and household chemical, and other packaged goods industries. Attendees include manufacturers, managers, engineers, production supervisors, purchasers, brand managers, package designers, product development professionals, and supply chain and logistics professionals from more than 40 vertical markets and companies of all sizes.

Attendees and exhibitors alike will have access to these must-see highlights at this year’s show:

The PACKage Printing Pavilion: Making its debut this year, the PACKage Printing Pavilion is the industry’s main stage for digital’s advantages for short-run, on-demand, cost-effective variable data and personalized packaging.

The Containers and Materials Pavilion: This year’s pavilion will address the latest innovations in paperboard, glass, metal and plastic. Flexible and resealable packaging options will also be on display, as will innovative containers and sustainable choices. The pavilion will also feature the Showcase of Packaging Innovations, sponsored by The Dow Chemical Company, where visitors can view the award-nominated packages.

The Confectionery Pavilion: Candy and snack connoisseurs can find the newest trends and technologies relating to aeration, batch refining, shaping, cluster production and cooling conveyers at this pavilion. Sponsored by the National Confectioner’s Association (NCA), it will also highlight innovations in easy-open packaging, portion control and much more.

The Reusable Packaging Pavilion: As demand rises for sustainable packaging solutions, the Reusable Packaging Pavilion, sponsored by the Reusable Packaging Association (RPA), is a hotspot for reusable products, services and solutions for increasing sustainability across the supply chain. The RPA’s Reusable Packaging Center within the pavilion will offer free presentations on case studies and best practices for incorporating reusables.

PACK gives BACK: Sponsored by Rockwell Automation, PMMI’s regular benefit returns to PACK EXPO International with a networking event in support of PACK EXPO Scholarships, a scholarship program for U.S. and Canadian students majoring in packaging and processing. Guests can enjoy beverages, light appetizers and a performance by stand-up comedian Sebastian Maniscalco. The fundraiser takes place Monday, with a reception at 4:30 p.m. followed by the performance at 5:30 p.m.

The Forum at PACK EXPO: Take advantage of free interactive presentations throughout the show. The Forum will feature 20-minute open sessions on the latest industry trends by the OpX Leadership Network, Institute of Packaging Professionals, Contract Packagers Association and PMMI Business Intelligence, followed by small group discussions and Q&A sessions.

The Innovation Stage: Visitors will have access to free educational programming at The Innovation Stage. During the show, free 30-minute seminars presenting breakthrough technologies and techniques will be scheduled and will focus on a wide range of industry specific solutions. Booths N-4560, N-4570 and N-4580

Industry Lounges: This is the place to be to network with peers, gain specialized insights and rest their feet at the show’s three industry-specific lounges. Networking receptions for Snack, Confectionery and Beverage Industry Lounges will take place in their respective locations on Tuesday from 3:30–5 p.m.

Student Opportunities

PACK EXPO International offers programs and activities aimed at getting students excited about careers in packaging:

The Amazing Packaging Race: Students are invited to discover the exciting possibilities in the packaging and processing industry by participating in the Amazing Packaging Race. In this fun and educational event, teams from colleges and universities across the U.S. race around the PACK EXPO International show floor to complete tasks at the booths of participating exhibitors. Wednesday, 9:00 a.m.–2:00 p.m., Booth E-350

Future Innovators Robotics Showcase: See high school robotics teams from across the country showcase their design, engineering and troubleshooting skills on Sunday–Tuesday, 9:00 a.m.–4:00 p.m., Booth E-6620.

- Ask about their robot design

- Inquire about the competition

- Check out their innovations

Registration information, which includes access to both PACK EXPO International and Healthcare Packaging EXPO, can be found at packexpointernational.com or hcpechicago.com.

|

Pack Expo Exhibitor Innovations

X-Ray Equipment Detects Smallest ContaminantsAnritsu Infivis (Booth E-7912) will introduce its second-generation XR75 DualX (Dual Energy) X-ray system. The XR75 is equipped with a dual energy sensor that detects contaminants as small as 0.4mm and improves detection of low-density or soft contaminants, providing virtually zero false rejects. In addition, the company will display their full line of X-ray inspection systems, checkweighers and metal detectors, as well as an upgraded version of QUICCA3 quality management and control system software.

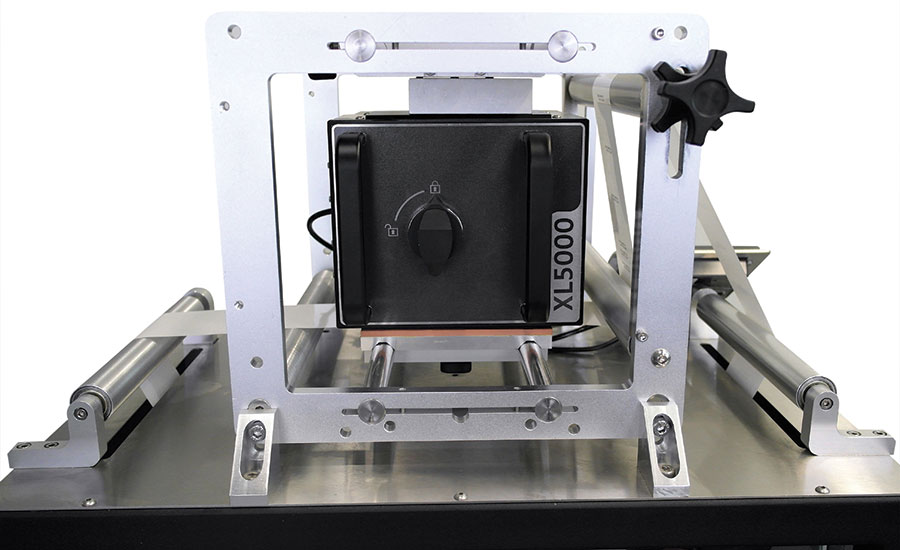

Thermal Transfer Overprinter Redefines Entry-Level PerformanceDiagraph (Booth N-5721) has launched the Allen XL5000 thermal transfer overprinter, a high-performance workhorse strategically designed to simplify real-time variable printing of expiration dates, lot codes, bar codes and logos onto web, flexible film and labeling applications. The Allen XL5000 provides quality performance on vertical and horizontal form fill and seal packaging lines for a variety of different packaging substrates including bags, pillow packs, cartons, blister packs, sachets and envelope packs.

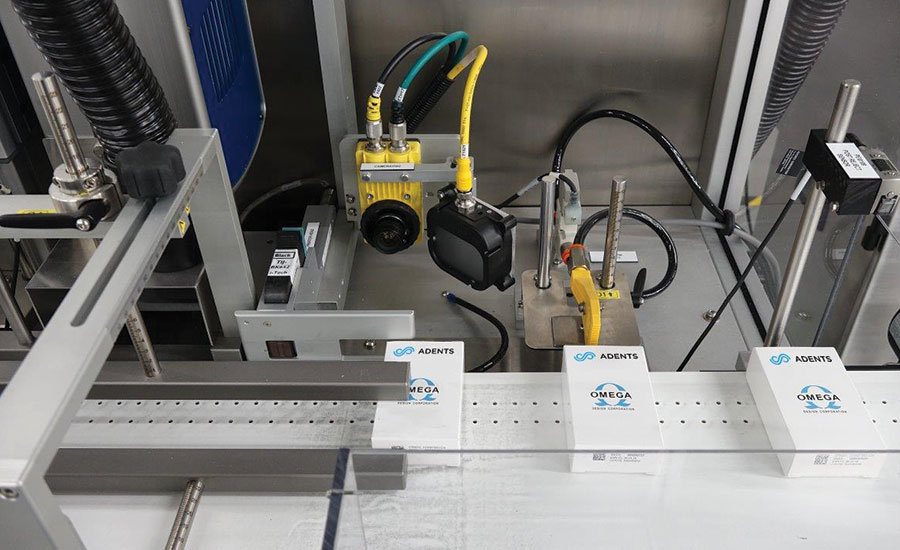

Multi-Factory Demo for Serialization SolutionsAdents (Booth W-820) will showcase a variety of serialization offerings. Adents partner companies — Omega Design Corp. (Booth #S-3714) and Pineberry Manufacturing (Booth S-1432) — will combine to portray a multi-factory serialization scenario using the cloud-based Adents Seriza solution, which provides unprecedented levels of flexibility and scalability. The setup will include real-time reports from several machines running simultaneously, demonstrating global connectivity that has been absent in most serialization efforts to date.

Lift ‘n’ Peel Seal for Tamper EvidenceSelig (N-4961) is unveiling Uni-Foam US, a co-extruded foam reseal liner that, due to having no pulp fibers, is a hygienic seal ideal for liquid, cream and gel applications. It conforms to industry standard density and provides excellent compression strength. The liner is available in a variety of thicknesses in white opaque color. The DELTASEAL 9000 is a two-piece waxless induction seal product that provides a hermetic seal to glass. The company will also exhibit the Lift ‘n’ Peel TamperSeal, in development for the pharmaceutical sector.

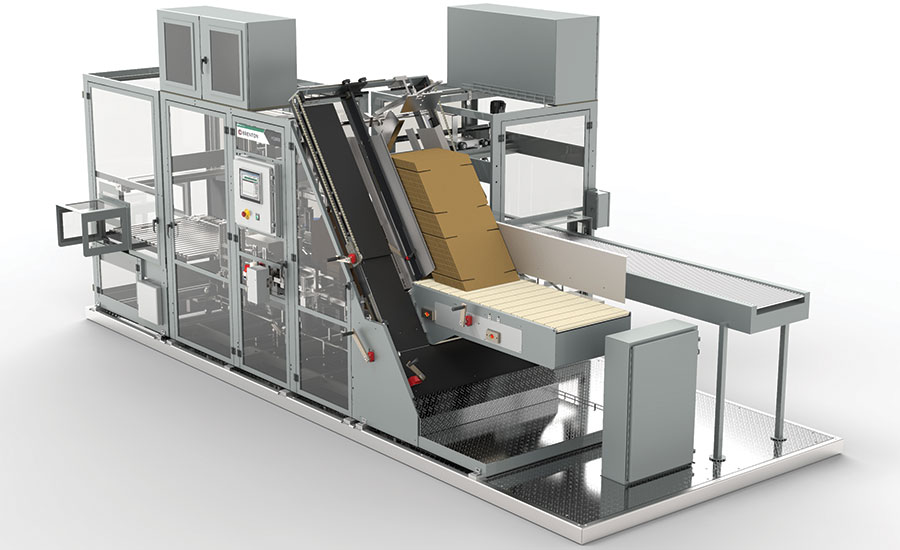

Compact Case Packer Gets SmallerBrenton (Booth S-3644), a product brand of ProMach, introduces a next-gen intermediate case packer, the Brenton M2000. The M2000 maintains the mechanical precision of the Mach 2 with updates that reduce the case packer’s footprint by 25 percent, shortens installation time and creates an easy to operate machine. Brenton designed the M2000 for higher uptime by making changeover more repeatable. The M2000 is rated at between 12 and 30 wrap-around, regular slotted cases or trays per minute.

Competitive Advantages with VFFS BaggerTriangle (Booth S-2014) has a variety of machinery to see. The Flex 1 Cartoner Gen 3, with a new automatic Changeover Wizard offers quick automatic changeover; model XYRJ VFFS bagger with rotatable sealing jaw runs package styles including three-sided seal, gusseted, pillow bags and stand-up pouches; the XYS08/7U with ultrasonic cross seal and back seal for applications requiring 100 percent seal integrity, such as leafy produce, liquids, cheese and confectionery; and the A918 combination weigher with improved efficiency comes in both in-line and belt-fed models, designed for a wide range of applications.

Next-Generation X-Ray Systems for Various ApplicationsEagle Product Inspection (Booth S-1721) will display the EPX100, a next-gen x-ray system for packaged foods, beverages and more. Also on display is the Eagle Tall PRO XS, suitable for the inspection of high-speed can, jar, bottle and composite lines. Side view detection provides 100 percent inspection for contaminants such as metal, stone, glass, dense plastics and calcified bone. Designed for meat and poultry, FA3/M X-ray system conducts in-line fat measurement and contaminant detection in fresh, chilled and frozen products.

Intelligent Case Packer UnveiledESS Technologies (Booth W-828) will debut its Predictive Maintenance (PM) Technology installed on the V30 robotic case packer. A combination of sensors and software monitors the “intelligent” machine’s overall performance, tracks routine maintenance and alerts operators about impending issues before the machine experiences a failure. Model V30 incorporates a FANUC M-20iA robot with ESS-designed end-of-arm tool (EOAT) and a servo collation system at the infeed that creates the required pack pattern. Robotic EOAT can be designed to handle products such as bottles with topserts, jugs, cartons, bundles, tubes and pouches.

Hygienic & Maintenance-Friendly Cup Filling SystemR.A JONES (Booth S-2501) introduces the latest addition to its Autoprod cup filling product line, the Autoprod CF-400. Completely redesigned with top hygienic operation, the Autoprod CF-400 also has new features engineered to provide greater flexibility and lower total cost of ownership. The Autoprod CF-400 is an in-line cup filling machine available in 5-, 6- or 8-lane configurations with production speeds up to 900 cups per minute. It also has a cup and lid vision inspection system and more.

Automated End-to-End SolutionsStäubli (Booth N-4848) will showcase solutions for case packing with its TS SCARA 4-axis robot. The TS robot is perfect for even the most sensitive applications, such as packaging delicate confections. Another highlight: An application for bakery, featuring a TX90HE 6-axis robot handling bread trays, scoring bread loaves and even washing itself down. And, the new Academia Box — a hands-on demonstration cell designed to offer instruction on how to code, program and utilize the TX2 robots using the new CS9 controller.

High-Speed, Low-Payload Robots Offer Consistent PerformanceKawasaki (Booth N-4943) has come out with two 6-axis vertically articulated robots with a maximum payload capacity of 7 kg and different reach. These are the latest additions to the company’s general-purpose R series line, ideal for a wide range of applications including packing, material handling and machine tending. The RS007N and RS007L robots offer consistently optimized performance by reducing cycle times. The RS007N features a 730 mm reach and the RS007L a 930 mm reach for greater flexibility in facility layouts.

Sanitary Conveyor Redesign Shows StrengthWith an improved frame design, added features and a positive drive option, Dorner’s (Booth N-4936) Next Generation AquaGard 7350 (V2) Series is the most advanced stainless conveyor for dry, wipe down and wet environment applications. The AquaGard and AquaPruf sanitary platforms are made with strong hygienic designs that minimize product debris from entering the food zones, and allow for fast and effective sanitation. See these and other conveyor platforms at the booth.

|