Packaging is ever-changing, with new forms, materials and machinery becoming available each year. That is why PACK EXPO is a must-see event for many in the industry. With this year’s show just around the corner, here is a sampling of just a few of the thousands of products that will be on display.

To see more products as the show approaches, visit www.flexpackmag.com or www.packexpolasvegas.com for updates.

Laminator, Adhesive Combo Provides Quick-Cure Solution

Nordmeccanica’s Duplex SL One Shot solventless laminator was developed in cooperation with Dow Adhesive for quick curing two-ply lamination. When the machine is used in combination with Dow Symbiex adhesives, it will allow unprecedented achievements that include: costs reduction; no need of a curing room; higher production speeds; quick curing (90 minutes to slitter); no need of a meter mixer dispenser. This technology is based on coating separately the two components of a solventless adhesive, each on one of the two webs to be laminated. At the lamination nip, the two components will come into contact and a reaction will be triggered that will quickly cure the adhesive.

Booth C-5006, www.nordmeccanica.com

ProAmpac Updates Pouches With Child Resistance Features

ProAmpac, the pioneer in child-resistant, reclosable, easy-open (CRREO) pouches, is updating its product line with an expanded range of sizes that will be displayed at PACK EXPO Las Vegas. “ProAmpac offers CRREO pouches with third-party certification to multiple performance standards, giving our North American customers the advantage of competitive pricing, shorter lead times and lower shipping costs compared to offshore suppliers,” says Adam Grose, chief commercial officer.

ProAmpac’s CRREO pouches meet all compliance requirements of the Consumer Product Safety Commission and the Environmental Protection Agency under the classification of ASTM D3475-08, Type XIA; they are tested in accordance with the Consumer Product Safety Commission Standards for Poison Prevention Packaging (C.F.R. Title 16 Part 1700), and are approved by the Government of Canada as part of its child-resistant testing.

The CRREO product line supports customers in cannabis, pharmaceuticals, health and medical, agriculture, chemical, and personal- and home-care markets.

Booth LS-6156, www.proampac.com

Eagle Product Inspection Showcases Solutions for Contaminant Detection

Eagle Product Inspection, with U.S. headquarters in Lutz, Fla., will exhibit solutions that help food and beverage companies enhance product safety, quality and traceability while simultaneously improving efficiencies.

One of those systems is the new Eagle Pack 240 HC, a high-performance compact x-ray machine designed for easy washdowns in harsh environments for packaged meat, poultry, dairy and other food applications where daily sanitization of equipment is mandatory. The machine provides superior x-ray performance and can detect foreign bodies in several package types, including chubs, over-wrapped trays, pouches, cartons, tubs, cups and plastic containers.

Eagle also will display the EPX100, an inspection tool for small and mid-sized operators and global companies who want to standardize their detection solutions across a variety of products. The EPX100, which inspects products in cartons, plastic containers, pouches and other formats, is suitable for a broad range of packaged foods and features adjustable power settings in a low-energy environment.

Booth C-1506, www.eaglepi.com

Heat Seal Cut-to-Length Unit Makes Pouches On Demand

AZCO Corp. will introduce their modular heat seal cut-to-length unit, which will allow companies to make pouches on-demand. After surveying many people in the medical device industry to learn and understand what current challenges they are, it was determined that pouches are a critical component in both manufacturing and packaging.

AZCO engineers designed a solution which will enable companies to make their own pouches on-demand, providing great benefits to the medical device industry. The compact system includes an unwind, a heat sealer, and a cut-to-length unit that will resolve many challenges and improve output and efficiency. Companies will have the ability to mark and serialize the pouches on-demand using thermal transfer, inkjet printing or laser marking.

The unit is designed to meet the medical packaging industry validation requirements for sanitary and sterile applications. A wide variety of bag materials can be used for the pouches, including medical polyethylene, polypropylene, heat sealable foils, paper/polyester, plastic and TyvekTM / Mylar film used for medical pouches and other sanitary packaging. Available options include a material flow package and a portable equipment stand.

Booth C-4333, www.azcocorp.com

Triangle and JDD Packaging Unveil Automated Rotary Pouch Machine

For packagers looking for an automated filling and sealing solution for premade pouches, Triangle Package Machinery and JDD Packaging Ltd., introduce to introduce the Triangle/JDD Rotary Pouch Machine. The rotary pouch machine is designed to fill Doy bags, 3-sided seal, flat pouches and stand-up pouches (SUP) at speeds up to 50 pouches per minute (ppm). The rotary pouch filler is available in two models: Model JRPM-8812 and JRPM- 81215.

Depending on the type of product being filled, the machine utilizes either a Triangle InLine Combination Weigher or other scale or auger to fill product into pouches. The system includes a series of stations to pick, open, fill, and seal the premade pouch. Other stations include a horizontal infeed belt to handle all pouch styles and a pouch outfeed conveyor. Standard features also include a pouch shaker to help settle product, as well as a Markem date coder.

According to PMMI’s 2019 Flexible Packaging Market Assessment, pouches account for the majority of package styles in the more than $230-billion global flexible packaging market. They are also the fastest growing category, with stand-up pouches predicted to comprise 28 percent of the demand for pouches by 2023 and side-sealed pouches expected to comprise 33 percent. The Triangle/JDD Rotary Pouch Machine is an ideal solution for businesses looking for the next step in packaging automation or entering new markets.

Booth C-2614, www.trianglepackage.com

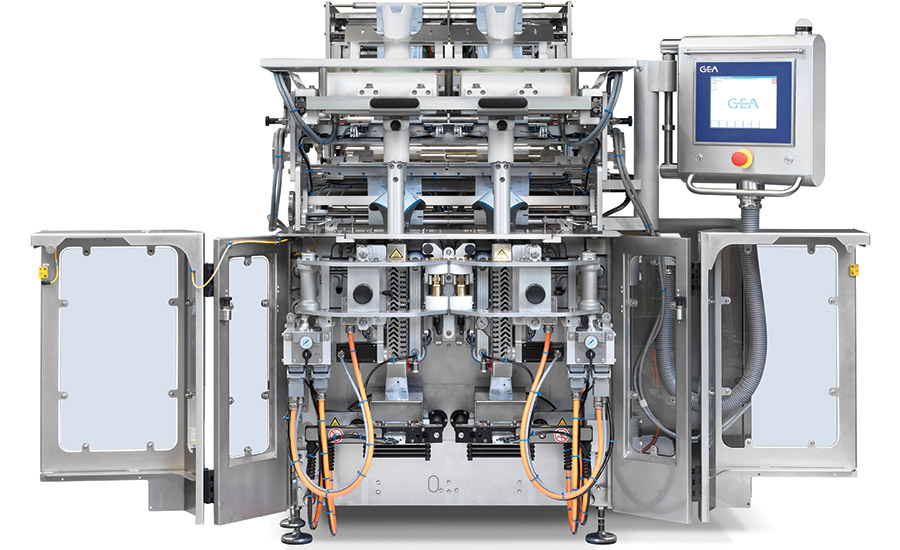

GEA’s Twintube Machine Designed For Flexibility

GEA will launch its SmartPacker TwinTube, a redesigned high-speed vertical packaging machine. The entire machine has been redesigned as a future-proof modular system with increased functional efficiency promoting higher operational uptime and ease of use.

The TwinTube is a continuous motion vertical machine, suitable for packaging small-sized, food products such as candy, nuts, dried fruit and other on-the-go products in pillow bags of different sizes. The machine is part of a complete packaging process with upstream and downstream equipment operating in a dry manufacturing facility. It operates with two parallel forming tubes, achieving combined speeds of up to 500 bags per minute (weighing 10 to 18 g each). It is also possible to run a different film reel for each tube, meaning calorie packs of different widths or designs can be simultaneously filled. A new feature to the machine is the jumbo roll, which allows film reels of up to 100 kg to be used for long production runs, which boosts operational efficiency.

The SmartPacker TwinTube is also equipped with automated web tracking. This means that if the film deviates from its path, due to variances in the film roll, the feature will correct the direction of the film automatically, without the need of manual adjustment. Ultimately this safeguards the quality of the resulting bags, while saving on downtime.

Booth LS-5905, www.gea.com

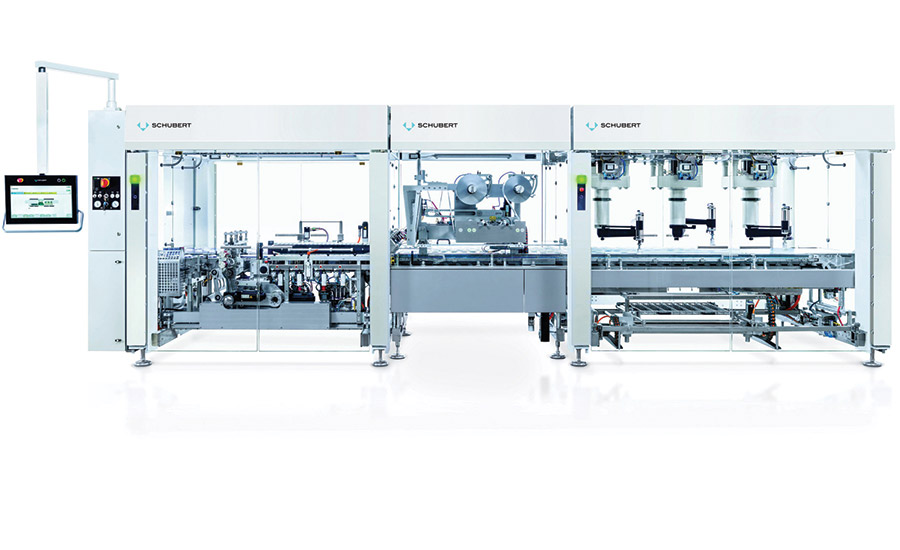

Schubert Presents Flow Packer

The Schubert Group will be exhibiting its new lightline Flowpacker. The machine combines a flow packer and a picker line in a single system, featuring state-of-the art sealing technology for packaging heat-sensitive products even more gently into flowpacks.

The lightline Flowpacker on exhibit was designed for a North American, family-run baked goods manufacturer to efficiently automate its end-of-line process by packaging freshly baked pastries into flowpacks. The integrated Flowmodul is equipped with Schubert’s new patented sealing technology. First, an ultrasonic sealing system closes the flowpack’s longitudinal seam, then a heat-sealing system with a flying cross-sealing unit is used. The flying cross-sealing unit adapts to the variable speeds of the upstream pick & place robots, ensuring high sealing quality with constant sealing times. Schubert’s pick & place robots guarantee flexible and gentle product handling.The robots can be seamlessly combined with other modules to integrate several packaging processes.

The machine also integrates Schubert’s 3D image recognition system to detect product position, orientation, height and quality, ensuring that the robots pick up only flawless products.

Schubert’s lightline machine series includes three compact preconfigured packaging machines: the lightline Cartonpacker for erecting, filling and closing cartons, the lightline Pickerline and the lightline Flowpacker for packaging products into flowpacks. A key benefit of all three compact preconfigured packaging machines is the unparalleled packaging machine availability they ensure in combination.

Booth US-7649, www.schubert.group

Sonics To Introduce Tabletop Pouch Sealer

Sonics will be introducing the Model T201WDB tabletop ultrasonic pouch sealer, intended for lab or pilot production use. Sonics’ new Model T201WDB pouch top sealing system is conveniently mounted on a base with two-hand tie-down palm buttons for manual operation. The system features Sonics’ patented seal geometry that results in the strongest possible seals. Also included is a custom hand-operated gripper mechanism to simulate real world pouch handling. Once pilot production has been completed, the sealer can be easily integrated into a pouch filling machine for fully automatic operation. Cool, ultrasonic tools enable sealing of heat-sensitive products without damage.

Booth LS-5822, www.sonics.com

Bosch Showcases High-Speed System For Packaging Bar Products

Bosch Packaging Technology will showcase its latest packaging system solutions for bars in a high-speed integrated system solution with features that take efficiency to the next level.

The exhibit consists of a high performance, indirect distribution station, a cardboard inlay feeding unit, a high-speed Sigpack HRM flow wrapping machine and a flexible Sigpack TTM1 topload cartoner.

The displayed system features an optional cardboard inlay module. The Sigpack KA forms flat, U-shaped or O-shaped cardboard inlays that are fed into the high-speed flow wrapper.

The Sigpack HRM is equipped with an HPS high-performance splicer and is able to wrap up to 1,500 products per minute. One of the highlights of the system is the Sigpack TTM1 topload cartoner. It stands out for its high product and format flexibility. In this configuration, the machine either loads the flow wrapped products into 24-ct display cartons or fills them directly into a tray. In addition, the integrated bar system is equipped with the mobile device-friendly operations and maintenance assistants that are both part of the Industry 4.0-based Digital Shopfloor Solutions portfolio. These user-friendly, intuitive assistants boost operators’ capabilities and guide them through maintenance and operative tasks.

Booth C-2800, www.boschpackaging.com