Multi-Conveyor (multi-conveyor.com) recently built a series of stainless steel, bolted construction conveyors, designed to transport flexible bags for seamless line integration. Initial conveyors transport the product on a slight incline with curve; then over power transfers transitions and a product turner. The product turner can rotate bags as needed or can be adjusted for straight running product depending on the customer's needs.

The product then travels through a customer supplied check weigher and metal detection system that Multi-Conveyor has integrated into the line. The vertical form fill seal bags pass through a compression belt that was requested to distribute product evenly for stacking and packing purposes.

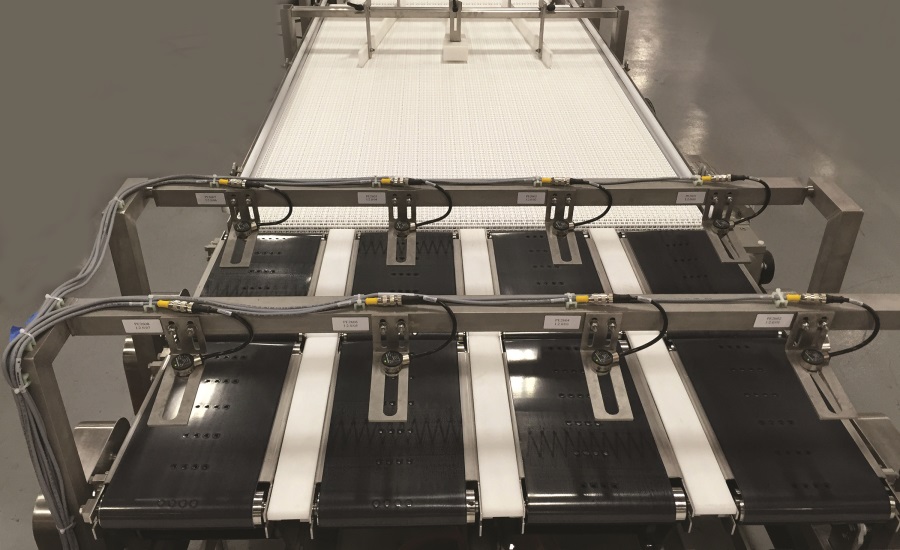

A retractable noser, complete with servo driven extend and retract for discharge, gently releases the flexible bags onto a lower belt traveling at a right angle. The lower belt has adjustable, multi-lane dividers that can be set up to handle either two or four lanes of product.

From there the bags move through servo smart belts that start and stop based on the weight and friction of the product for continuous movement and seamless merge.

Multi-Conveyor provides all controls including touch screen capability, variable frequency drives, servo drives and other devices as needed while using UL listed components, NEMA 4 enclosures and accommodations as our customers require.