Sidel (sidel,com), a leading global provider of PET solutions for liquid packaging, introduced a revolutionary PET blowing solution - the Sidel Matrix™ blower eHR - to produce hot fillable PET bottles of consistently high quality. By heating the mold via electrical heat resistance (eHR) instead of oil, the Sidel Matrix blower eHR achieves various benefits in terms of bottle quality, performance, process flexibility, uptime, energy savings and operator safety.

Enhancing consistent performance, saving energy

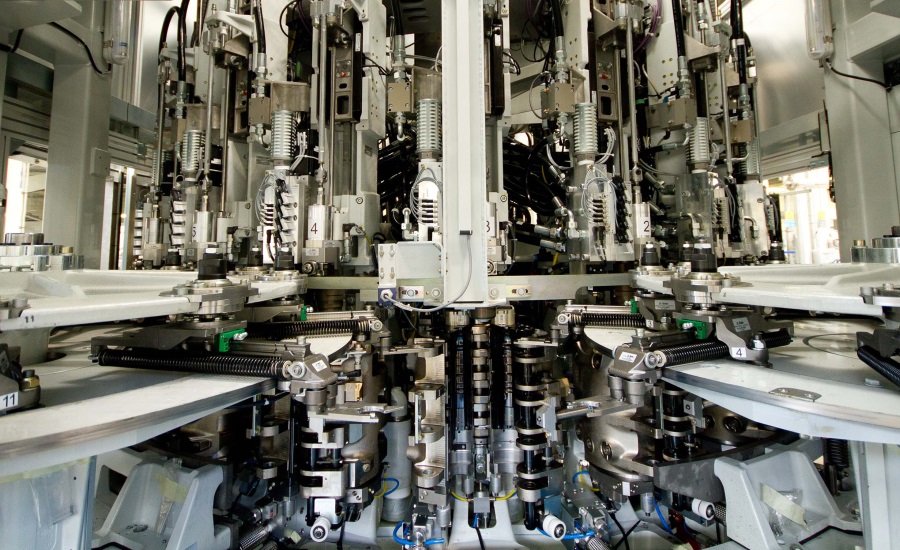

Sidel's new solution uses innovative eHR electrical heating instead of the traditional oil heating of the molds and reaches the required temperature three times faster, ensuring consistent high quality from the first bottles produced. Probes are directly located in each mold shell to regulate the temperature of the PET bottle as it is formed, and temperature discrepancies between different blowing stations are kept to an absolute minimum. As a result, all bottles undergo the same thermal conditioning and meet consistent high quality standards.

The latest generation of blowing valves on the Sidel Matrix blower, combined with the mechanical blow nozzle system, the electrical stretching and the new automation architecture allow increased control of the blowing curve. Consequently, mechanical output is increased by up to 2,000 bottles per hour per mold, representing a speed improvement of more than 10% compared with the previous generation of Sidel HR blowers.

Electrical heating also offers energy savings of up to 45% compared with the previous generation of Sidel SBO Universal HR blowers. The performance of the Sidel Matrix Ecoven with the infrared lamps and ceramic technology reduces the use of power by a further 25%, and by implementing the AirEco2 air recovery option, air consumption can be reduced by up to 45%.

Hygiene and safety

As it does not use oil to heat the molds, the Sidel Matrix blower eHR eliminates issues caused by leakages, thus improving operator safety. The risk of contamination is also excluded, because electrical stretching does not use lubrication above the neck of the bottle. In addition, the Sidel Matrix blower eHR benefits from other proven Sidel Matrix developments, such as oven ventilation with air filtration for more hygienic production.

Since the heat is focused on the molds, which are insulated from the mold supports, the ambient temperature inside the Sidel Matrix blower eHR remains lower than in a traditional HR blower. This eliminates thermal constraints on other machine components and creates safer intervention conditions for equipment operators.

Staying ahead with innovative developments

During its 35 years of PET experience, Sidel has delivered almost 560 HR blowers around the world. This expertise is complemented by four decades of experience in the hot filling of beverages, first in glass containers and then in plastic.

The new Sidel Matrix blower eHR benefits from this knowledge and combines the innovative eHR electrical heating solution with the latest proven technologies of the Sidel Matrix blowers. Mechanical settings are the same, and 73% of the eHR blowing station components are similar to those of standard Sidel Matrix blowers. The eHR solution can be combined with the Sidel Matrix Intelliblower™, which brings control and self-regulation to the blow molding process, independent of any operator intervention. As it is contactless, electrical stretching is efficient and robust, delivering consistently high quality PET bottles and contributing to increased output.

Benefits of eHR blowing with Sidel Matrix Combi Hot Fill

This new electrical heating resistance blowing process is integrated into the Sidel Matrix Combi Hot Fill that combines the blowing, filling and capping functions in one machine. Sidel Combi systems offer line efficiency levels up to 4% higher than standalone machines, and by reducing the number of machines involved, can cut operating costs by up to 12%. The resulting smaller footprint and controlled production environment ensure increased hygiene and food safety.

The Sidel Matrix Combi Hot Fill has electronic filling valves equipped with individual flow meters for accurate volume dispensing with minimal wastage. Hygienic design and contactless filling valves ensure complete beverage safety. Sidel’s solution can accommodate a broad range of beverages with and without pulp or particles, and it can easily manage neck changeovers.