The Lush Black Pot was recognized earlier this week as the first FDA PP PCR resin and rigid packaging application for cosmetics use during the 2017 APR Plastics Recycling Showcase.

Held in conjunction with the Plastics Recycling Conference, KW Plastics (kwplastics.com) and Lush Fresh Handmade Cosmetics presented their respective technical challenges of the package before being selected for the 2017 APR Plastics Recycling Showcase by the Association of Plastics Recyclers (APR).

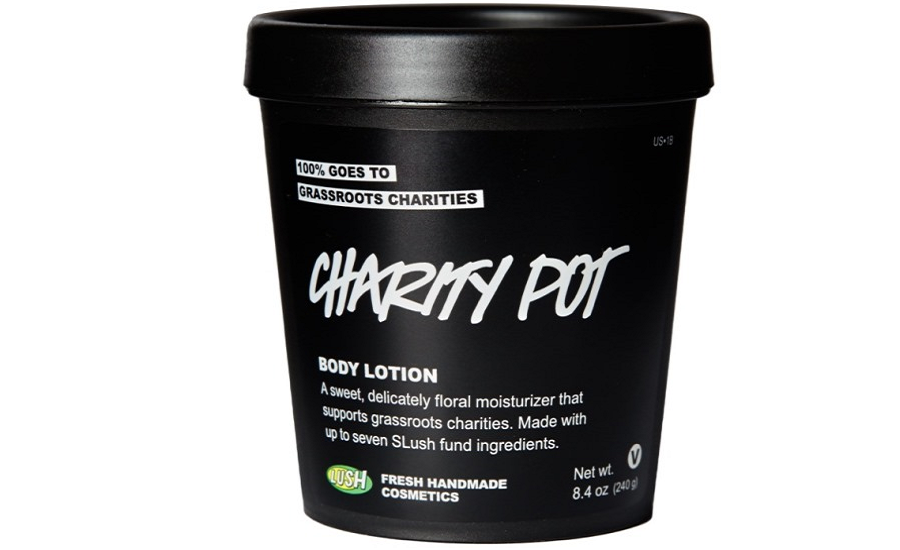

The Lush Black Pot is a 100% postconsumer polypropylene package that includes an injection molded container and lid. The package, made for cream and lotion, is made with KWR621FDA and KWR621FDA-20 resins that have received FDA letters of non-objection for 100% content.

“It was imperative that KW Plastics was able to provide consistent quality and contaminant-free feedstock to our molding partner, Plascon Plastics, so that we could have confidence in our packaging,” explains Gary Calicdan, senior buyer packaging & print of Lush Cosmetics.

“We were committed to providing a package that was as sustainable and innovative as our products. We were unwilling to compromise quality, such as improper fitting lids, discoloration or over threading, or performance so it was vital that our PCR choice would allow for a sturdy, perfect fit for the pot and lid without any leaking issues.”

According to Pedro N. Morales, director of sales and marketing for KW Plastics, the largest technical challenges were not simply in achieving the specifications, but more importantly, being able to maintain the strict source control of feedstock and regulatory compliance requirements of a cosmetic package.

“We understood that our resin not only had to offer the environmental and economic advantages but performance was nonnegotiable,” Morales says. “The aesthetics, dimensions, stability, stack and impact strength were of key importance for the mating lids and pots.

“The Lush Black Pot is a wonderful example of the success both a resin supplier and brand owner can enjoy when each link in the supply chain understands the respective challenges and commitment to using PCR.”

According to APR technical director, John Standish, APR is always looking to recognize innovations that have a positive impact on the ability of a package or container to be recycled. “We recognize that innovation drives the growth of recycling and is essential to the success of the plastics recycling industry. The Showcase identifies, highlights, and commends the industry’s leading innovations developed by APR member companies.”