Never stop moving

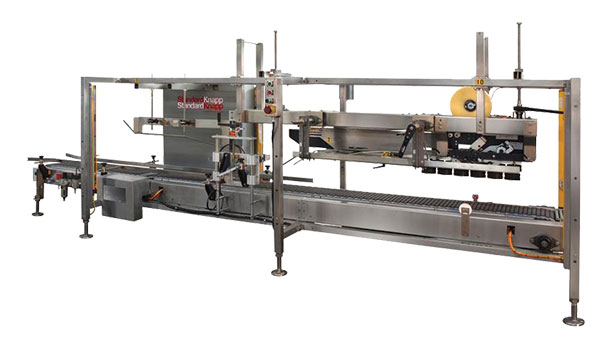

Standard-Knapp (standard-knapp.com) offers the Model 199 continuous-motion case sealer, ideal for high-speed sealing of primed flap and re-shipper cases (RSC). The high efficiency Model 199’s inline design allows for high speed, consistent sealing of all incoming cases, whether close-coupled to a case packer discharge or installed as a stand-alone machine. The continuous-motion case sealer offers speeds of 50-75 cases per minute, and features quick complete changeover in less than two minutes.

Standard-Knapp (standard-knapp.com) offers the Model 199 continuous-motion case sealer, ideal for high-speed sealing of primed flap and re-shipper cases (RSC). The high efficiency Model 199’s inline design allows for high speed, consistent sealing of all incoming cases, whether close-coupled to a case packer discharge or installed as a stand-alone machine. The continuous-motion case sealer offers speeds of 50-75 cases per minute, and features quick complete changeover in less than two minutes.

Using a one-hose, four-gun, hot melt glue system or optional tape dispensing unit, the Model 199 sealer glues or tapes and folds the top flaps into place. An on demand servo-controlled flap tucker ensures precise timing and a consistent glue pattern or accurate tape placement. A pneumatically controlled flap tucker is also available for slower speeds. The Model 199’s one hose and four low-cavity glue guns ensure reliable gluing and virtually no-drip operation.

The Model 199 was carefully designed with fewer moving parts to reduce downtime. The low maintenance design features a rust-proof stainless steel frame. A durable, well-tested compression section uses a standard friction belt to easily handle lightweight cases and eliminates the need for side belts.

A B C, easy as one, two, three

For beverage manufacturers who are looking to maintain optimum product integrity during packing and shipping, A-B-C (abcpackaging.com) offers the Model 800 case packer with features to accommodate shrink wrapped multi-packs of beverage and juice boxes. This high performance case packer provides product accumulation, case erecting, packing and sealing at speeds up to 25 cases per minute, and offers many variations in packing patterns and product feeds while maintaining optimum product integrity during packing and shipping. It incorporates features for gentle product handling to eliminate scuffed overwraps or damaged graphics. Each product load is stacked in a specially designed accumulation section that is tailored for the product. After accumulation, the entire load is transferred through collapsible funnel gates that open into the erected case, for smooth product transfer that maintains maximum package integrity.

For beverage manufacturers who are looking to maintain optimum product integrity during packing and shipping, A-B-C (abcpackaging.com) offers the Model 800 case packer with features to accommodate shrink wrapped multi-packs of beverage and juice boxes. This high performance case packer provides product accumulation, case erecting, packing and sealing at speeds up to 25 cases per minute, and offers many variations in packing patterns and product feeds while maintaining optimum product integrity during packing and shipping. It incorporates features for gentle product handling to eliminate scuffed overwraps or damaged graphics. Each product load is stacked in a specially designed accumulation section that is tailored for the product. After accumulation, the entire load is transferred through collapsible funnel gates that open into the erected case, for smooth product transfer that maintains maximum package integrity.

This packer is equipped with A-B-C’s standard features to increase line productivity including: a heavy gauge steel frame that is welded and bolted for strength, combination pneumatic/mechanical operation that provides the precision of mechanical motion and the security of easy release simply by dumping the air supply; plus electrically interlocked gull-wing guard doors that stop the machine and release air when they are opened and simple change parts and crank adjustments for running a variety of case sizes. This case packer is a reliable, flexible and cost effective way to automate case packing needs.

Wrapping up the case

Blueprint Automation (BPA, bpa-flexolutions.com) debuts its new CPIII Wrap-Around Case packer equipped with auto-changeover. The case packer automatically erects, loads and closes wrap-around cases, trays, try-lid combinations and RSC cases. It features hygienic design built for food applications such as snacks, dairy, confectionery, sugar, coffee, nuts, spices and more.

Blueprint Automation (BPA, bpa-flexolutions.com) debuts its new CPIII Wrap-Around Case packer equipped with auto-changeover. The case packer automatically erects, loads and closes wrap-around cases, trays, try-lid combinations and RSC cases. It features hygienic design built for food applications such as snacks, dairy, confectionery, sugar, coffee, nuts, spices and more.

The stainless construction feature frameless, clear acrylic safety guard with the control box integrated into the top of the machine. The modular set up allows for a wide variety of product handling systems and allows for customization based on the customer’s needs.

Two heads are better than one

Motion Controls Robotics, Inc. (motioncontrolsrobotics.com) has formed a strategic partnership with Combi Packaging Systems LLC (combi.com) to integrate robotic pick and place technology with ergonomic hand packing equipment. They are launching a new automated case packing product called the Ergobot®, an automated version of Combi’s proven Ergopack® ergonomic hand packing station. Motion Controls Robotics will apply its expertise in robotic packaging, case packing and palletizing to expand the ability of both companies to fully automate case packing and packaging tasks.

Motion Controls Robotics, Inc. (motioncontrolsrobotics.com) has formed a strategic partnership with Combi Packaging Systems LLC (combi.com) to integrate robotic pick and place technology with ergonomic hand packing equipment. They are launching a new automated case packing product called the Ergobot®, an automated version of Combi’s proven Ergopack® ergonomic hand packing station. Motion Controls Robotics will apply its expertise in robotic packaging, case packing and palletizing to expand the ability of both companies to fully automate case packing and packaging tasks.

“The collaboration between Motion Controls Robotics and Combi will give customers of existing or new ergonomic hand packing stations the opportunity to fully automate case packing operations,” says Scott Lang, President of Motion Controls Robotics. “We can create retail ready packages and perform case packing tasks that are difficult, ergonomically challenging, or unsafe for humans.”

Benefits of the Ergobot® robotic case packer include:

- Lean operations make manufacturers more cost competitive globally

- Increased throughput and reliability

- Vision technology improves quality control and enables 100% product tracking and traceability

- Lot verification and serialization

- Easily accommodates variable pack counts

- Integrated, proven case erection and taping

- Increased packing rates with multiple robots

- Multiple product packaging with manual or automatic robottool change and menu driven product selection

Consistent performance for an inconsistent world

The world of shipping is a balancing act between speed and dependability, and the less predictable variables of customer demands. To help professional shipping managers meet the need for flexibility with reliability, 3M (3M.com/packaging) is introducing a new line of 3MMatic™ Case Sealers – each designed with interchangeable tape heads (2 and 3 inch), rugged dual extruded columns and 3M’s signature quality and service.

The world of shipping is a balancing act between speed and dependability, and the less predictable variables of customer demands. To help professional shipping managers meet the need for flexibility with reliability, 3M (3M.com/packaging) is introducing a new line of 3MMatic™ Case Sealers – each designed with interchangeable tape heads (2 and 3 inch), rugged dual extruded columns and 3M’s signature quality and service.

For shippng managers tackling the challenges of unpredictable box sizes, the 3M-Matic Random Case Sealer 7000r Pro is the ultimate solution, handling up to 24 different case sizes per minute.

Boxes as small as 6 inches long x 6 1/2 inches wide to as large as 26 inches wide and unlimited length won’t confound the photo eye detectors and electro-mechanical height adjustment features, which keep the 7000r Pro taping heads on target and get customer orders out on time.

If the need for speed outweighs size variability, an alternative is the new 3M-Matic Adjustable Case Sealer 7000a Pro. The 7000a Pro allows for easily accessed manual side handle adjustments.

It can consistently seal up to 40 cases per minute to keep pace with high demand peaks. A third new case sealer, the 8000a, also is designed to handle high volumes and is equipped with a side belt drive system which is ideally suited for sealing tall and tippy boxes.