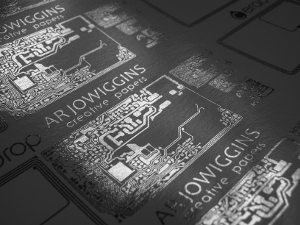

Arjowiggins Creative Papers is proud to announce that PowerCoat, its paper for printed electronics, has been awarded a second industry prize. The Printing Industries of America have awarded it an InterTechT Technology Award.

Arjowiggins Creative Papers is proud to announce that PowerCoat, its paper for printed electronics, has been awarded a second industry prize. The Printing Industries of America have awarded it an InterTechT Technology Award.

The InterTech Awards are given to “unique and innovative technologies” that are “expected to have a significant impact on the graphic communications and related industries.” As a recipient, Arjowiggins Creative Papers will be presented with an InterTech Lucite star. Earlier this year, PowerCoat received a trophy in the IDTechEx Printed Electronics Europe/Graphene LIVE 2013 Award. Both prizes reflect the interest this printed electronics trend is generating as it makes its way to major printed electronics shows in Europe, Asia and the U.S. Its ultra-smooth paper base, flexible substrate and environmental credentials make it a notable new entrant in the printed electronics market.

Arjowiggins Creative Papers’ PowerCoat is a cellulosic paper formulation and coating process that reportedly provides an ultra-smooth and flexible substrate that facilitates the seamless integration of printed electronics and printed graphics, opening possibilities in the packaging, advertising, textile and pharmaceutical industries.

PowerCoat is designed to be a sustainable substrate with polymer-like smoothness (as low as 10 nanometers) that offers excellent printability and ink adhesion properties without any plastic content. Its surface is intended to reduce the consumption of silver inks and support high-resolution fine patterning (down to 5μm) of

any solution-based electronic layer.

When conventional papers are printed with conductive inks, several issues are generally raised: ink is too easily absorbed by the paper causing unnecessarily high levels of ink consumption; surface roughness leads to low resolution patterning and decreased conductivity; yellowing and colour fading, as well as altering of physical characteristics of certain substrates, occur during sintering (the process which fuses conductive inks to the substrate).

Using existing pressroom environments and processes, the thermal stability of PowerCoat aims to allow for precision control during sintering. Its structure can withstand the high temperatures required for low-resistance, silver ink without discolouration. It can endure a sintering cycle set at 200°C for 5 minutes,

as well as flash (photonic) sintering without any noticeable change in physical characteristics, promoting conductivity and faster printing times.

PowerCoat is designed to be ideal for roll-to-roll processing due to its high dimensional stability under mechanical tension. It makes high resolution printing of fine patterns possible with fewer registration issues.

For a long time, it has been said that “plastics make it possible”. PowerCoat has proven that paper is just as reliable for applications in the world of Printed Electronics, all while being much less hazardous to the environment than plastics.

With its properties and smoothness, PowerCoat makes way for more efficient use of chemicals and inks and is 100 percent recyclable, biodegradable and FSC certified.

According to the company, a 5 to 10 times reduction in silver ink consumption has been demonstrated compared to conventional screen printing technology when using PowerCoat in RFID antenna inkjet printing.

PowerCoat's value at the moment revolves around the following:

• Resistors, capacitors, self-inductance and other passive components

• More efficient creation of RFID antennae where less ink can be used

• Sensing technology such as walls and handheld devices

• Electrodes for batteries,circuitry for display, lighting, etc.

• Integration of intelligent functionality in disposable labelling and packaging

The paper enables passive and interactive circuitry to be integrated with existing printed products. In this way, the flexible paper substrata facilitates the integration of a whole range of electronic functions into graphics, from embedded RFID tags to condition-sensitive sell-by dates on fresh produce. Natural roll-to-roll capability allows it to produce large area products such as sensor walls and flexible displays.