Before they’re boxed, wrapped, lidded, or otherwise ready to be cased and shipped, packaged goods are inspected for physical contaminants or product anomalies that can cause major issues once they leave a plant. Manufacturers can reduce risk and ensure quality by utilizing the industry’s most advanced, accurate and reliable inspection and detection systems from Anritsu Industrial Solutions USA (anritsu-industry.com), including turn-key X-Ray, Checkweigher, and Metal Detection equipment, along with proprietary processes and software.

“Manufacturers are at the front line of safety and quality before products get into consumer’s hands and households. They’re also looking at total cost of ownership and return on investment, while running products at high operating speeds. We work with packaged goods companies of many types to deliver safety, quality and ultimately, efficiency and profitability of their products and production lines,” says Erik Brainard, President and CEO of Anritsu.

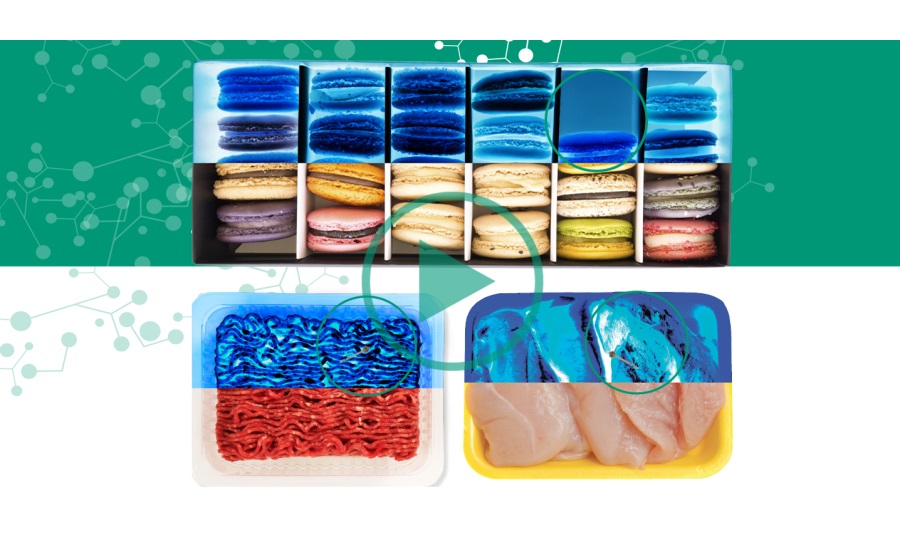

According to Brainard, Anritsu is constantly working on new inspection and detection technologies and innovations. The company’s advanced X-Ray solutions include Ultra High Definition (HD) X-Ray technologies that detect the most minute contaminants, down to 0.2 mm diameter ferrous, non-ferrous, and stainless steel spheres at production line speeds. The DualX system from Anritsu allows packaged goods companies to see through multiple packaging materials to detect contaminants and inspect for missing pieces, count and mass through virtual weighing.

Anritsu's Metal Detectors provide another point of inspection and detection for foreign materials in packaged goods. The company’s industry-leading Dual Wave Metal Detection Systems maximizes detection of both ferrous and non-ferrous metals through the ability to set two simultaneous frequencies, independent of each other.

At the finished product stage, Checkweighers validate the weight of the product and/or case. Anritsu offers more than 150 Checkweigher systems, along with a combination Metal Detector-Checkweigher system. The company’s Smart Measure Function provides a versatile, flexible way to decrease false rejects and reduce product giveaway to increase ROI.

Most recently, to provide a more comprehensive, integrated solution for meat processors, Anritsu developed a proprietary four-step process called Detection360that precisely detects risks associated with product contaminants and missing items through X-Ray, Checkweighing, and Metal Detection solutions. The Detection360 process includes four key phases to help processors gauge their needs and determine the solutions that work for their own operations and products: Discovery, Mapping, Integration, and Performance Phase.

To equip packaged goods companies with the tools, support, and training they need to best run and diagnose their lines, Anritsu offers a lifecycle management program called Performa360™\.