PACK EXPO Las Vegas and the co-located Healthcare Packaging EXPO, presented by PMMI, the Association for Packaging and Processing Technologies, takes place Sept 23-25. The event will cover 900,000 net sq. ft. of exhibit space, with 2,000 exhibitors and 30,000 attendees from nearly every market. If you are new to PACK EXPO Las Vegas — or a seasoned attendee — here are tips to help manage your time and schedule at the show. And make sure to read our September issue, as we will have much more coverage on what’s happening at this year’s event.

- My Show Planner: Use this online tool to create a customized plan at the show.

- Mobile App: Use the app for news, events, shuttle times, interactive floor plans and more, happening in real time.

- Show Guide: You will find the PACK EXPO Show Guide at each hall entrance, with all of the information you will need to get you through the show.

- The First-Timer’s Lounge: Enjoy free refreshments, planning assistance, comfortable seating and charging stations — and meet other newbies. Open daily 10 a.m. – 4 p.m. Upper South Hall, Room S-227.

All of the resources listed above can be found at packexpolasvegas.com.

Hot Spots This Year

The Robotics Zone: New this year, the spot for all things robotics takes up an entire zone in the North Hall to showcase the latest technologies in robotics. You will be greeted by an Omron robot greeter, and see a robot playing the piano, interactive dice playing cobots dice and more.

The Forum makes its PACK EXPO Las Vegas debut with free, 45-minute learning sessions on the latest industry trends, including hands-on activities, small group discussions and a Q&A each day of the show.

Packaging & Processing Women’s Leadership Network (PPWLN) Breakfast: Launched in 2016, PPWLN serves to recruit, retain and advance women in processing and packaging. Ellen Ochoa, the first Hispanic woman to ever go to space, is the keynote speaker at PPWLN’s next breakfast at PACK EXPO Las Vegas. The breakfast is on Tuesday, Sept. 24 at 7:30 a.m. Register at pmmi.org/ppwln.

PACKage Printing Pavilion: New also at Pack Expo Las Vegas, this pavilion will focus on the advantages of digital printing showcasing the latest in cost-effective solutions for smart, short-run, on-demand, cost-effective, variable data and personalized packaging. Central Hall

CareerLink LIVE: PMMI’s online job board is going live for the first time in Las Vegas. CareerLink LIVE is an opportunity for PMMI, CPA, IoPP members and consumer packaged goods (CPG) companies to meet with students and veterans pursuing careers in packaging and processing with one-on-one informational interviews.

PACK gives BACK benefit, sponsored by Rockwell Automation, featuring the legendary Steve Miller Band. A portion of the proceeds from this year’s event will support NS2 Serves, a nonprofit dedicated to helping recent U.S. military veterans transition from combat boots to business suits. Register at packexpolasvegas.com/pack-gives-back.

Vision 2025: Before the show opens, join us for breakfast and gain valuable connections, insights and new perspectives. Come to one of three sessions for an interactive discussion on key industry topics with your peers. Participation is free on a first come, first serve basis. Sessions will take place all three days, 7 – 9 a.m. Register on the website.

PACK EXPO Las Vegas and Healthcare Packaging EXPO present the opportunity to see solutions from other vertical industries to help address production challenges and boost innovation; evaluate new products, technologies and suppliers; and discover what’s trending and find unexpected solutions from other industries. PACK EXPO brings together industry professionals from around the world to catch up on the latest technologies and trends. Registration, which includes access to both EXPOs, is $30 through August 30th, after that the price is $100. For more information and to register, visit packexpolasvegas.com or hcpelasvegas.com.

|

Exhibitor Innovations Some of the innovations attendees will discover on the show floor are below. Save the booth numbers on your My Show Planner tool. Single-Source Bag-in-Box System Bosch Packaging Technology (Booth C-2800) will demonstrate its single source bag-in-box system, which covers the entire line from bagmaker and settler to product handling, endload cartoner and case packer. Focusing on the bakery and cereal markets, two machines will be on display to show efficient packaging of crackers: The product handling machine Kliklok Interceptor, which is designed to deposit bags directly onto its main conveyor by a bagmaker, and the Midrange Endload Cartoner Kliklok MEC will be exhibited for the first time as a part of a bag-in-box line. The machine stands out for its future-proof sanitary design, tool-less changeover and easy operator access. The control package pocket rededication allows the cartoner to maintain optimum speed matched to processing capacity. In addition, Bosch will introduce the new Elematic 2001 case packer as a virtual reality demo.

Two-in-One System for Sandwich Operations Campbell Wrapper Corp. and Compass Industrial (Booth C-2629) will display an advancement in sandwiching operations, which includes the all-new Compass MD2/Row Combiner integrated with Campbell Wrapper’s latest iteration of the Revolution horizontal flow wrapper. The 1,600 sandwich per minute MD2 features tool-less, easily removable rails, magazines and stencil for wash-down, allergen cleaning. Advanced design eliminates the pin chains usually associated with sandwiching by using clean design pin bars. Sandwiches move through the machine consistently with reduced noise for better line operator experience.

Added Features Improve Quality, Productivity, Worker Safety METTLER TOLEDO Safeline (Booth C-2023) has added improvements to its GF metal detector line that increase productivity, enhance brand protection and improve product and process quality. These improvements are aimed at making metal detection a smoother, safer, less disruptive process that adds to the profitability of operations. The four new improvements are the RT (Reduced Test) Mode; ATS (Automatic Test System; e-Drive technology to increase the detection of smaller and spherical contaminants; and Emulation, which enables the remote monitoring of detector performance using hand-held wireless devices. Using VNC (Virtual Network Computing) technology, Emulation allows operators to mirror the Human Machine Interface (HMI) of one or more Profile metal detectors onto remote networked devices, including mobile phones, tablets and laptops.

ESS Robotics Integrates FANUC SCARA Robots TaskMate Robotic Systems from Ess Robotics (Booth N-236) now integrate FANUC America’s new line of SCARA robots to create an ultra-compact robotic cell that integrates easily with cartoners, case packers and monoblock filler/cappers for collation and machine loading and unloading. The small size of the FANUC robots, combined with their high flexibility, allow ESS to place the robot within the machine frame, unlike the larger robots that require a separate robotic cell with additional safety guarding. This reduces the system footprint and cost and minimizes the required guarding. TaskMate systems can be integrated with new machines or retrofitted with existing packaging machines to create a high-performance solution for automating manual processes. The FANUC SR Series offers high speed and flexibility in collating product prior to cartoning or case packing, loading machine infeeds and unloading machine discharges.

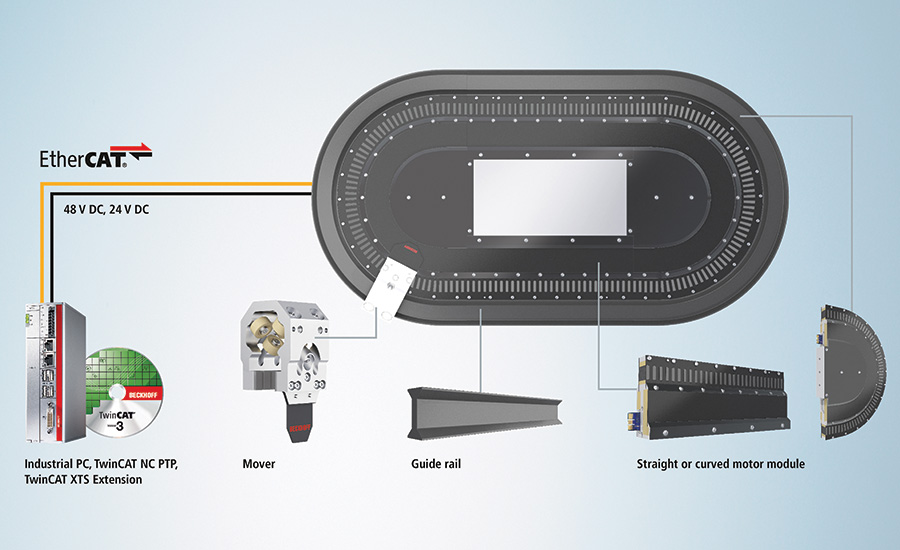

Linear Drive Technology Boosts Manufacturing Beckhoff Automation (Booth LS-6149) is bringing its new eXtended Transport System (XTS) to the show floor. The EtherCAT-enabled XTS offers capabilities for motion control and mechatronics by combining the advantages of proven rotary and linear motion principles into a new modular platform. With a compact and flexible design, the advanced mechatronic system can reduce machine footprint up to 50%. XTS contains all functions necessary to support efficient integration for motion control applications in many industries. With attached mechanical guide rails, XTS motor modules feature directly integrated power electronics, EtherCAT communication and position measurement. An unlimited number of wireless XTS movers can be controlled with high dynamics at up to 4 m/s on extremely customizable paths.

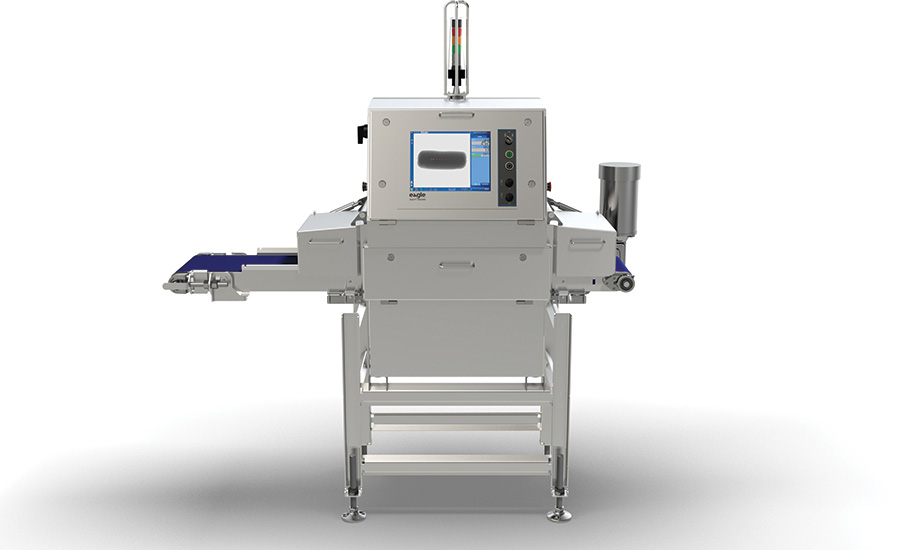

Solutions for Contaminant Detection, Quality Assurance Eagle Product Inspection (Booth C-1506) will display many inspection systems this year, including the new Eagle Pack 240 HC, a high-performance compact X-ray machine designed for easy washdowns in harsh environments for packaged meat, poultry, dairy and other food applications requiring sanitized equipment. Also, the EPX100 is an inspection tool for small and mid-sized operators looking to standardize their detection solutions across a variety of products. The EPX100 inspects products in cartons, plastic containers, pouches and more, and is suitable for a variety of packaged foods. For those using cans, jars and bottles the Tall PRO XS could fit the bill. It provides 100% inspection for hard-to-find contaminants in tall, rigid containers including glass, metal and ceramic containers as well as plastic containers, cartons/boxes and pouches. The system can run at line rates in excess of 1,000 ppm.

In-Line Box Filling System Fills by Various Methods On display for the first time will be an In-Line Box Filling System. In-Line, Side-by-Side and Over/Under Box Filling Systems are new to the Dynamic Conveyor line (Booth LS-63170). All of these box filling systems are capable of filling by part count, cycle count or weight. Offering a smooth transfer of boxes up to 200 lbs., the systems are automated and allow for unattended operation of accurate filling with simple control set-up and an easy to read visual indicator. Also in the booth will be the company’s DynaClean sanitary conveyors and DynaCon reconfigurable conveyors.

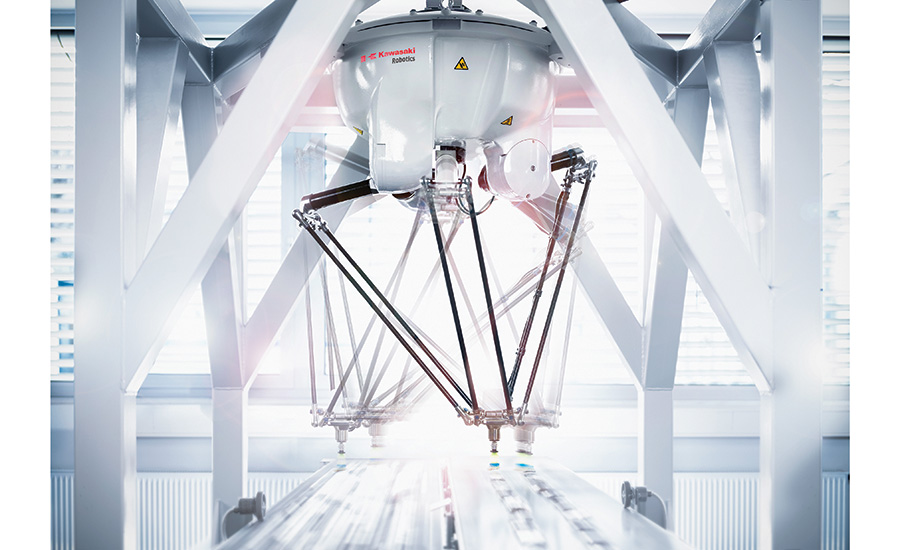

Leveling Up with Collaborative, Delta and Palletizing Robots Kawasaki Robotics (LS-6314) will showcase the new collaborative duAro2 with an increased vertical stroke of 550 mm and payload of 3 kg will be featured in a customizable packing cell. With demand for personalized products and services on the rise, the low-cost and flexible duAro2 cell serves as an example of how robotic automation can help face such demands. Also new to the show lineup is the high-speed Kawasaki YF003N delta robot, which offers a payload capacity of 3 kg, wide motion range and speeds of 222 cycles per minute for a 1 kg payload operation. A YF300N and a high-speed, invert mounted RS007L robot will pick & place product for packaging cosmetics. Also, a high-speed CP180L robot capable of palletizing rates of 2,050 cycles per hour will palletize bags and boxes ranging in weight and size.

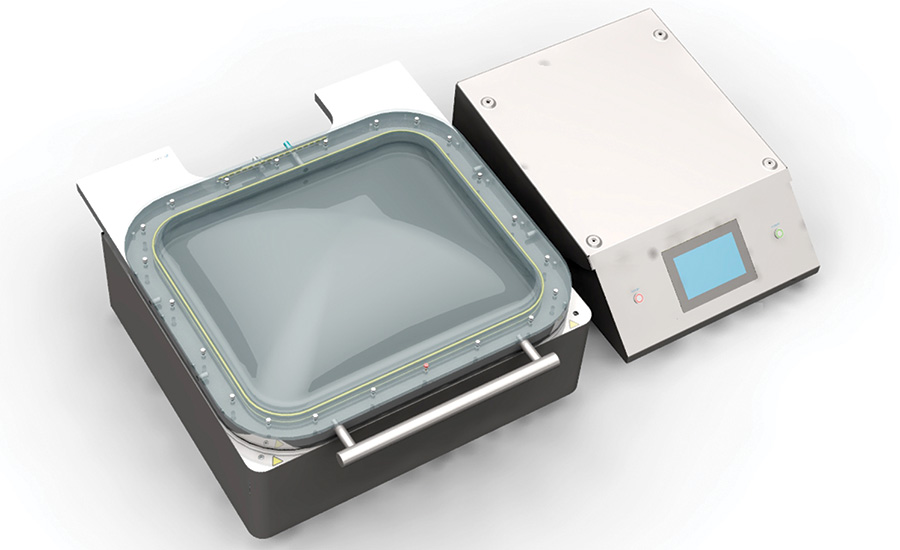

Leak Detector Can Test Multiple Products at Once INFICON (Booth US-7777) will unveil the Contura S600, which features an oversized test chamber designed to test products sold for bulk retail and foodservice applications as well as large format Modified Atmosphere Packaging (MAP) and flexible packages. The S600 model relies on a proprietary differential pressure method to detect both gross and fine leaks and offers a faster, easier and quantifiable alternative to methodologies like water baths and gas-based testing. With the new test chamber, food manufacturers can increase efficiencies by testing multiple products at the same time. The S600 is ideal for food applications such as pet food, meat and poultry, baked goods, snack foods, confectionery/candy, cheese, grains and cereals, prepared food and produce.

|