Home » Keywords: » conveyor system

Items Tagged with 'conveyor system'

ARTICLES

Machinery

Selecting the Right Sanitary Conveyor Platform for Food Packaging Application

Conveyors are a prime target for contamination, but understanding the nuance of how equipment works with specific applications ensures upgrade success.

March 8, 2022

Pack Expo Las Vegas: A Preview

Get on track with tips for the show and exhibitor previews.

August 12, 2019

Machinery

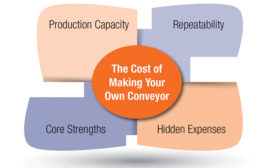

Make Vs. Buy Conveying Systems

The decision to make or buy a conveying system relies on four main factors.

March 12, 2019

Machinery Technology: Conveying

Matching Conveyors with Applications

Follow these tips for a clear path to the best return on investment

November 12, 2018

Machinery Technology: Conveyors

Choosing a new conveyor

Determining the best system for operational efficiency.

September 13, 2017