The products below will be shown at PACK EXPO Connects in Virtual Showrooms. These only touch the surface, as to-date there are more than 2,500 demos to view. Visit the Live Demo section on PACK EXPO Connects.

Triangle Machine’s Double Bagging Line Requires no Extra Floor Space

With a machine width of only 36 inches, Triangle’s Model CSB Compact Sanitary Bagger runs bags from 2.5” – 13” wide and up to 15” long. Run individually or pair two baggers side by side with a single scale to maximize production in a 72” footprint. Its design allows two compact baggers to be installed in the same space required by one typical VFFS machine. In addition to saved floor space and increased production, benefits include improved OEE, a clean-in-place design, stainless-steel frame, easy changeover, and labor savings. Visit Triangle’s virtual showroom.

Food Service Disposables, Ecommerce Bagging Applications by Rennco

Rennco will be demonstrating its vertical packaging capabilities that focus on both the food service disposable market and ecommerce bagging. Rennco is an industry leader in the development of automated vertical bagging machines for the food service industry. Its machinery excels in disposable applications involving cup counters, lid packaging and plate infeed systems. One virtual presentation will focus on vertical packaging applications for food service disposables and other market segments. The second will show how Rennco’s semi-automatic vertical bagging machine is an ideal solution for packaging round, odd-shaped items and ecommerce applications. The Model 301 Packaging System for ecommerce is able to right size the package. Visit Rennco’s virtual showroom.

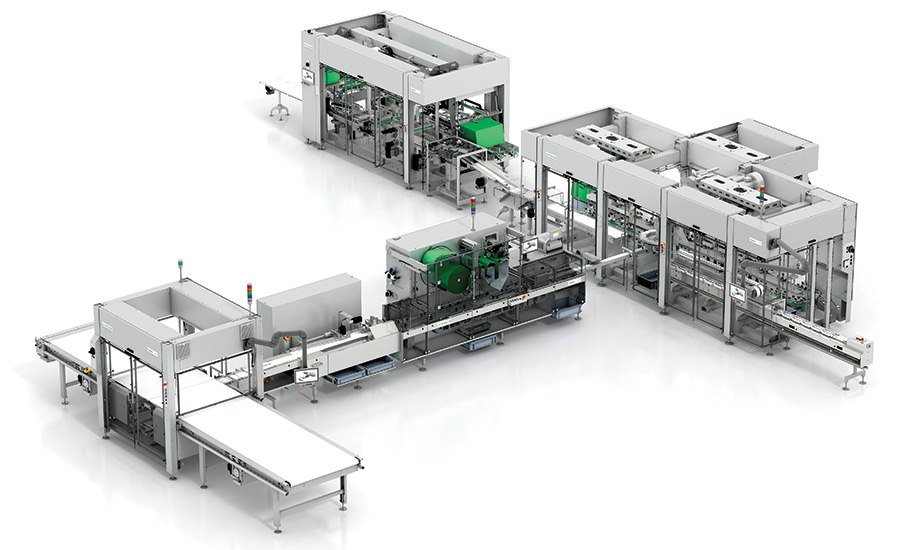

Syntegon to Showcase Food & Pharma Packaging & Processing Technology

In a series of video and Q&A sessions, Syntegon is showcasing its intelligent and sustainable technologies for the pharmaceutical and food industries, including customer services and digital solutions. For the food industry, Syntegon is showcasing its primary and secondary packaging portfolio, with a focus on sustainable solutions. In flow wrapping and bagging, Syntegon machines can run fully recyclable mono-material films and paper films. Carton blanks made from recycled fibers or grass fiber can be processed on their secondary and transport packaging equipment. For the pharmaceutical industry, Syntegon is demonstrating its long-standing processing and packaging expertise for solid dosage forms. With regard to liquid pharmaceuticals, the company is presenting solutions ranging from small and micro batch sizes to high-performance machines. Participants will also gain insight into Syntegon’s latest and most advanced automatic inspection technology and solutions for high-potent drug processing. Visit Syntegon’s virtual showroom.

Orion’s Pallet-Wrapping Capabilities Can Improve Safety and Efficiency

Orion Packaging Systems, a division of ProMach, will demonstrate its latest innovations in stretch-wrapping technology. Orion’s new Dual Carriage MA-DX2 stretch-wrapping system uses dual 30” Insta-Thread film carriages and 28 RPM counter-balanced rotary arms to wrap up to 100 pallets an hour. See how easy it is to gain newfound efficiencies through high-speed wrapping. Orion will also showcase the differences between entry-level semi-automatic stretch wrappers versus hand wrapping. While many organizations still hand-wrap loads and pallets, efficiencies through time, film savings, safety, load stability and others factors can be achieved by installing an entry-level semi-automatic stretch wrapping machine. A case study shows how the Orion MA-DX LoPro Drag Chain Conveyor System helped a beverage distribution center greatly improve its speed and efficiency in wrapping and moving tall pallets of product. Visit Orion’s virtual showroom.

METTLER TOLEDO’s AdvancedLine Checkweigher Offers Fast, Accurate Weighing in Washdown Conditions

Built for harsh environments, the C35 from METTLER TOLEDO delivers precise weighing results on a stable weighing platform resistant to high-pressure washdown and most caustic detergents. The system frame is designed according to hygienic principles, with easy access for cleaning and sloped surfaces to discourage liquid collection. The system supports speeds of up to 250 packs per minute and a weighing range from 25 g to 7 kg. The C35 is fit for use in a wide range of production situations that require 100% reliable weight control, including food processing. A wide range of optional conveyors and handling features, including guiderails to ensure smooth product handling, provides for optimal transport of open products such as jars, trays and cans. The C35 provides positive ROI through increased efficiency, lower production costs, and reliable service. Visit METTLER TOLEDO’s virtual showroom.

Quest Industrial’s Robotics & Vision-Guidance Systems for Various Markets

Quest Industrial will be hosting nine virtual demonstrations focusing on robotics and vision-guidance systems for the food, beverage, dairy and packaging industries.

Quik Pick Robotic Case Packer: This high-speed robotic case packer is quick, accurate and compact. A main differentiating point with the Quik Pick is its speed and flexibility. With the QPick custom case packing software, the Quik Pick can be configured to pick up as many as 1,000 pieces per minute.

Boxed-Bot Robotic Palletizing: This space-saving robotic palletizer features a small footprint starting at just 8’x10’. The Boxed-Bot allows an operator to design and produce exact pallet patterns quickly and easily from bags to boxes and other product types. QF 100 Robotic Primary Packaging: For packaging produce, this series of robotic primary packaging is family of solutions designed to automate the filling of single and multi-compartment trays, bowls and clam-shell containers. Visit Quest Industrial’s virtual showroom.

Syntegon Reveals Kliklok ACE Carton Former to North America

Syntegon Technology will reveal its new Kliklok ACE (Advanced Carton Erector) topload carton former. The Kliklok ACE was developed with a particular focus on ergonomic design, sustainability, and increased efficiency. The newly integrated Flex Feeder ensures reliable and safe carton control through the entire process. The Kliklok ACE range runs at up to 80 cycles per minute with single, double or triple heads and is suited for a number of food applications, such as bakery, snacks, cereal bars, frozen/prepared food, tea and coffee, as well as non-food products. The new carton former can form lock-style and glue-style cartons on the same machine, offering manufacturers full flexibility. Syntegon also provides the machine with ultrasonic technology, an industry first in this segment. Both the lock and ultrasonic versions, are glue-free, making them a real sustainable option. The Kliklok ACE range can handle different carton format sizes, ranging from a blank size of 190 mm length x 122 mm width to 800 mm length x 600 mm width. Visit Syntegon’s virtual showroom.

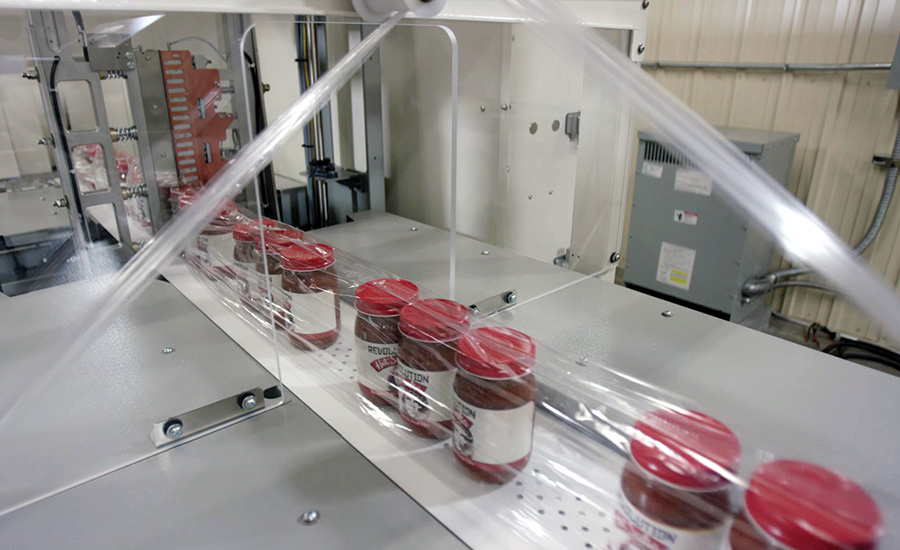

Texwrap to Demonstrate Shrink Wrapping, Bundling and eCommerce Packaging Solutions

Texwrap shrink wrappers can reduce overall operations costs. The integration of our vertical shrink wrapper with a filler allows users to collate and shrink wrap retail-ready multi-packs immediately after filling. Additionally, the company’s Ecommerce Auto Mailer solution provides increased throughput, decreased DIM weight for shipping and up to 50% material cost reduction. High-speed shrink bundling systems bring value to customers through integration with tray packers, collations systems, labeling, palletizing and other equipment. The benefits of this integration include product uniformity, reduced label and material costs, as well as saving space. The high-speed horizontal wrappers bring a fast return-on-investment to applications including fresh and frozen pizza, cakes, pies and other delicate food and bakery products. These wrappers come with innovative technology, such as a patented 5-axis servo orbital seal system, TVS2 side seal and other advances. Visit Texwrap’s virtual showroom.