Home » Keywords: » food packaging trends

Items Tagged with 'food packaging trends'

ARTICLES

Spotlight Feature

Using IIoT to Improve Packaging Line Performance

Incremental implementation of the IIoT by plant engineers and other experts is the best route to success.

September 10, 2019

Brand Packaging: Packaging Redesign

Is It Time For a Food Package Redesign?

These steps will help you to make a decision whether it’s time to redesign or leave it alone.

April 1, 2019

Market Trends

Tending the Flock in Poultry Packaging

Poultry packaging has come out from the sidelines with smart technologies, bold colors and innovative materials.

February 12, 2019

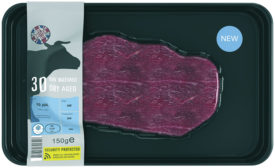

Market Trends: Meat Packaging

Meating the Packaging Challenge

The meat packaging sector demands high-quality packaging solutions, requiring excellent presentation with a focus on shelf-life extension.

August 14, 2018

Market Trends: Snack Food Packaging

A New Culture in Snacking

Consumer packaged goods companies rush to take a bite out of growing snack foods market.

June 15, 2018

Cover Story: Food Packaging

What’s Cooking in Food Packaging?

Consumer trends driving developments that enhance food shopping

February 12, 2018