“Our customers didn’t ask for vision systems,” says Martin Taube, Global Product Manager of Inspection Systems at Bizerba, “but they are under more pressure than ever to produce perfect products as a result of tighter regulations and higher standards. Adding vision was the way to give them what they needed.”

With 144 years of history in the food production business and customers around the world, the company has seen the rise of many technological innovations and process improvements.

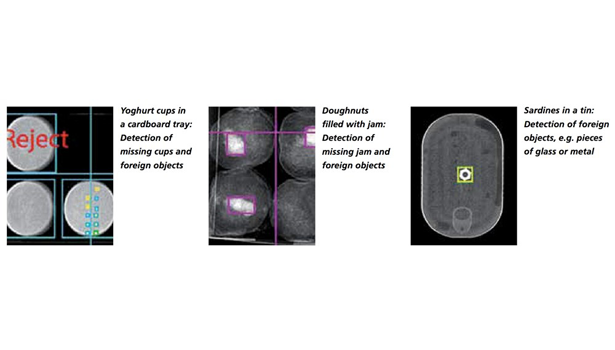

The goal here was to put an end to costly product claims from customers. Bizerba uses line scan cameras in its Bizerba Vision System (BVS) to inspect production line food products, like packaged meats — the kind you see in the supermarket. The system inspects the bar code on the label, the text, and even the product itself.

Food Production, Through the Machine’s Lens

When integrated into labelling lines, the BVS will automatically inspect the label position and the text printed on it as well as the color of the foil. Packaging sizes and bar codes can also be verified using the system. “Having the right label applied to the intended package is not something we leave to chance,” says James Farmer, head of Product Development at Bizerba North America. With a background in both mechanical and electrical engineering, he isn’t blind to his customers needs.

The inspection system keeps a sharp eye out for imperfections in packaging and labelling—performing crucial checks that prevent recalls and product claims. Any packaging that fails a producer’s standards is identified quickly and segregated from production.

“One of my favorites so far, has been an application at a Swiss cheese factory. You have all different sizes and shapes, from one millimeter to 90, and you have to deal with all of it.”

Customer Focus

For Bizerba, customer service stays high on the priority list. To continue to deliver that meaningful product experience, and make it better and longer lasting, the company is constantly pushing forward.

Keeping things easy and convenient for their customers is part of that list, and is reflected in the systems they develop. “We’ve created a standard tool set that was tailored to our industry.” Before, Bizerba didn’t have this standard toolset, and their product was application based. “Today, our customers can buy a standard piece of equipment, bolt it up, train it, and go.”

“That’s another thing that really sets us apart,” says Taube, “our commitment to a good user interface.” This approach ensures that training requirements for new machinery—or new employees—is as short as possible. It also makes the technology Bizerba packs into their systems more accessible. The user interface makes it easier to take advantage of innovations in machine vision.

Machine vision still has a long runway for food production and inspection. It’s a critical industry with a lot of room to explore and it’s not yet clear how far the technology can go. These challenges are meant to be crossed, and it all comes down to the drive to find the smallest, fastest system that is low cost and delivers the best performance.