As the flexible packaging industry expands, the variety and types of heat sealers has increased to meet the demand. While there are many choices of highly specialized sealing machines from which to choose, there are only three common methods for heat sealing: Impulse sealing, direct, or constant heat sealing, and ultrasonic sealing. Understanding the benefits and potential drawbacks of each method can go a long way in helping the purchaser make the most appropriate choice for their particular application.

Impulse heat sealing

Impulse heat sealing is commonly used for joining thermoplastic materials such as Polyethylene and Polyurethane that require a moderate temperature to establish an effective seal. This versatile method may also be used for sealing Mylar, Tyvek® and a wide variety of other bag, pouch and tube materials. Impulse sealing is often used to seal multi-layer, metalized and oxygen barrier bags and pouches. Properly configured, an impulse heat sealer can join two sheets of fairly heavy thermoplastic materials.

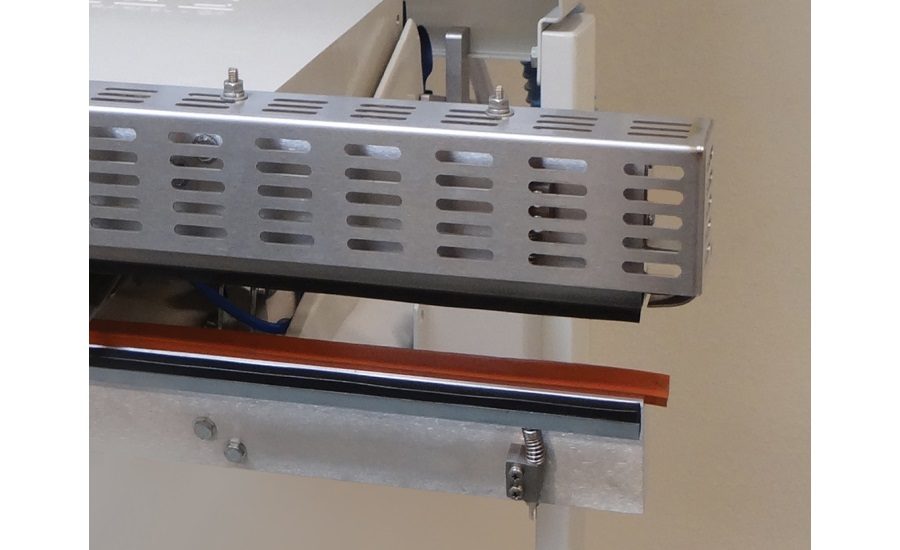

Impulse heat sealers may have one or two (round or flat) replaceable heating elements made of a specialized material - usually a Nichrome alloy - located in the top and/or bottom of the sealing bars. The Nichrome element is sandwiched between a resilient, heat resistant rubber pad and a protective Teflon fabric. After the materials to be sealed are positioned in the sealer jaws, the jaws close and are held in place by pneumatic or mechanical pressure. An electric current then momentarily heats the Nichrome element for a predetermined amount of time to achieve the necessary sealing temperature. The jaws continue to hold the work piece in place after the heat cycle is complete (again, for a predetermined amount time) to permit the welded material to cool and fuse fully. Largely determined by the material being used, heat sealing usually requires a specific combination of heat, pressure and time between each step.

One of the advantages of impulse sealing is its inherent safety. High heat is only present when the sealing jaws are closed under pressure and the sealing element is energized. This means that it is virtually impossible to become burned upon contact with the sealing jaws. While the jaws can retain a small amount of residual heat over hours of continuous use, the temperature never reaches a dangerous level. By controlling the temperature of the seal wire, impulse sealing can accomplish everything constant heat can achieve. One key advantage of impulse sealing has to do with the fact that the user can control the cooling cycle while the material is still in the sealing jaws and under pressure. Another advantage in impulse sealing is the reduction in operating costs. Because the sealing elements are energized for a very short period of time per sealing cycle, power consumption may be reduced. Lastly, unlike constant heat sealers, impulse sealers can regulate cool times, plus they do not require a “warm-up” period to reach operating temperature.

Constant heat sealing

In contrast to impulse sealing where the seal bar temperature rises and falls quickly, constant heat sealing provides a higher controlled temperature at the sealing jaws, making this process more adaptable to certain thermoplastic or poly-coated materials. A constant heat sealer can join two sheets of thermoplastic materials as long as the material does not overheat causing it to become thin and weak. Like impulse sealers, constant heat sealers use one or two heated sealing bars – but unlike the impulse method, the sealing bars are continuously held at the prescribed sealing temperature at all times. Once they have reached operating temperature, constant heat sealers can maintain an accurate level of temperature control in the sealing bars. Though seal bars remain hot, most modern constant heat sealing machines have protective barriers that are designed to reduce or eliminate burn injuries. Constant heat sealers do offer some advantages over impulse sealing. In impulse sealers, the constant heating and cooling cycles can cause stress and deformation of the sealing element unless a temperature controller is used, which limits the wire deterioration. Constant heat sealing can reduce repetitive expansion and shrinking. For certain materials, (many multi-layer, Mil Spec bags for example), constant heat sealing is the preferred approach as heat is readily available at high temperature.

Ultrasonic heat sealing

Ultrasonic sealing is a technique developed in the 1960’s, whereby pressure and high-frequency vibrations are applied to two pieces of material (often rigid plastic) to establish a seal or weld. While not used in the flexible packaging industry, ultrasonic sealing is commonly used for joining plastics components in the automotive, aerospace, and consumer products industries as well as in many other industrial applications where rigid plastic is required. One of the advantages of ultrasonic sealing is the ability to bond dissimilar materials – including plastic to metal and plastic to carbon fiber materials. In order to bond the materials, ultrasonic sealers require three main components to resonate and interact at the exact same ultrasonic frequency. The key components are the transducer (sometimes called a converter), which transforms an electrical signal into a physical vibration; the booster, which controls or modulates the vibration; and the sonotrode, which actually transmits the vibration to the work pieces. The benefits of ultrasonic sealing are that it is cleaner and faster than conventional joining methods that use adhesives or solvents, plus the low thermal impact on the work piece facilitates a greater variety of materials that may be joined.

Seal integrity and join strength

A critical consideration in the medical device manufacturing industry, seal integrity and join strength can be tested in a number of ways, and the rigor of the test depends on the individual requirement. It is important to note that there can be some confusion between what constitutes seal strength and seal integrity. A strong seal does not necessarily equate to seal integrity. This is because a seal that passes a standardized strength test may not establish the microbial barrier (due to the presence of channels and voids in the seal) required for sterile barrier device packaging. Heat sealed bags and pouches may be tested for pull strength, the ability to sustain a vacuum, burst strength, seal permeability, the ability to maintain a seal under sterilization procedures as well as various other criteria. The current industry standard for sterile barrier testing procedures are described in ASTM F88/F88M-09 (seal strength test), ASTM F2054M-13 (burst testing), and ASTM F1140/1140M-13 (whole-package, internal pressurization). Impulse sealing can be used for all pouches while constant heat can only be used on material, which does not melt.

Heat seals are created millions of times per day, around the globe. The success of your sealing processes depend on your understanding of the specific procedures, methods and materials required for achieving a good quality seal for your specific application.