Sustainability is more than a trend; it’s a call to action, and one that consumers across the globe are becoming more involved in, pushing brands to set goals that help reduce climate change by 2030. As a result, consumers are making purchasing decisions based on how brands align with their values.

According to a 2019 study by IBM and the National Retail Foundation, consumers are prioritizing those brands that are sustainable, transparent and aligned with their personal core values. The same study shows that one-third of all consumers today will stop buying their preferred products if they lose trust in the brand, and one-third of consumers have already stopped purchasing their longtime favorite brands in 2019 due to these concerns.

With this in mind, brands are making changes to better respond to sustainability needs, selecting partners who prioritize the environment to help produce packaging that aligns with what consumers are looking for. Here are four ways partners can help brands achieve their sustainability goals.

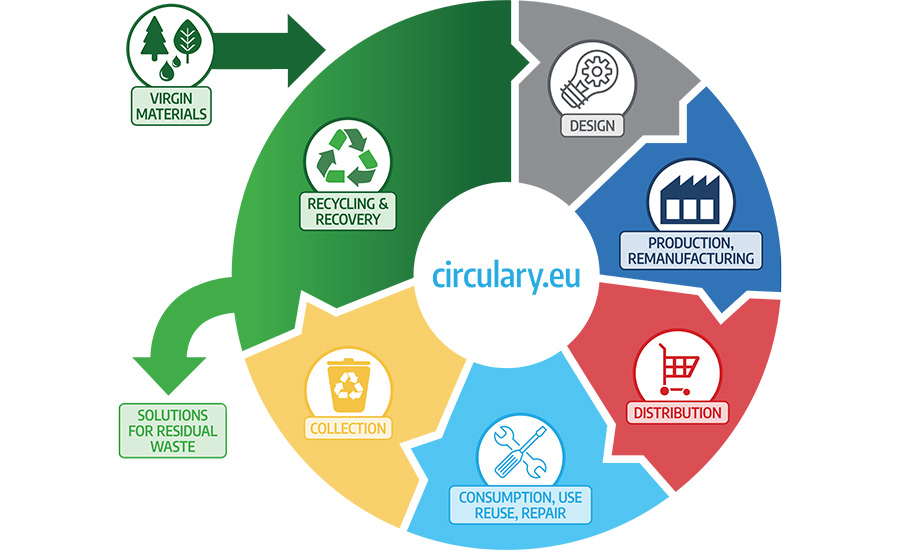

Illustration courtesy of www.circulary.eu

Using Sustainable Raw Materials

To help brand owners achieve sustainability goals, partners should focus on using renewable resources and raw materials that promote recyclability, bio-renewability and compostability.

With the aggressive shift toward becoming a circular economy, natural resources would be used, broken down and recycled for use again. For example, a polyethylene terephthalate (PET) bottle with a shrink label on it could be used, the label de-seamed and the bottle recycled, allowing those same raw materials to be used repeatedly.

Current solutions in the marketplace enable brand owners to increase the recyclability of their products that use shrink labels. Currently, offerings exist that provide solvent-based, de-seaming adhesives that replace the traditional solvent seam on the label, allowing easy removal during recycling for an improved, label-free process for recycling PET containers.

To help promote bio-renewability, the packaging industry can reduce greenhouse gas evolution by substituting conventional water-based inks with more bio-based options that deliver equal or superior performance, at no additional cost. With full adoption of current commercially available solutions, global CO2 emissions can be reduced by over 30 percent or approximately 700,000 tons per year.

According to The National Association of Printing Ink Manufacturers (NAPIM), bio-renewable inks are derived from tree, plant, insect, and/or animal materials. These include gums, resins, waxes, solvents, oils and other polymer building blocks.

Finally, sustainable raw materials can help produce compostable packaging for brands, which can help decrease their carbon footprint and return nutrients to the soil at a package’s end of life. The overall compostability of a package, labels included, directly relates to its components — inks, substrates and more — which must comply with set rules determined by region.

Photo courtesy of Sun Chemical

Minimizing Waste

With inks being a high cost for brands, ink partners are offering solutions that can help save money on restocking inventory and reducing waste. Color matching tools and dispenser programs are available which allow for the right color to be printed consistently, helping ensure brand color matching in their packaging without the need for reprints.

Solutions in the market can offer a change in ink measuring and mixing process for brands, minimizing the color matching errors and using only the amount of ink needed for a particular print job. The result is reduced ink inventory on shelves.

With less print runs and higher accuracy, this color-matching technology uses less fossil fuel than the traditional method, in turn, helping brands reach their sustainability goals.

Operating with Efficiency

Printers and converters who prioritize operating with energy efficiency can also help brands to achieve sustainability goals. For example, conventional mercury and LED curing systems produce no volatile organic compounds (VOCs). Additionally, LED curing systems do not produce ozone or contain mercury and utilize about 50-60% less energy than conventional mercury UV lamp systems.

Unlike the conventional mercury lamp system, which runs for about 2,000 hours, the LED energy curing system runs for over 20,000 hours while producing the same level of cure in terms of hitting specific curing targets over time.

There is also less heat transfer so brands can run more sensitive substrates to help lightweight the substrates more significantly. For example, it’s possible to run thinner film to produce shrink sleeves with LED systems. Inks used in such a system and application also offer the advantage of requiring less energy than mercury vapor lamps.

Recognizing the regulatory measures in place globally, brands switching to UV LED curing are using low migration and low odor inks to produce the required consistent migration results over time.

There are also dual cure ink offerings on the market that enable package printers who are in the process of transitioning to more environmentally efficient presses to use the same ink on LED and mercury vapor cured presses. Narrow web presses in the market are often hybrid configuration, utilizing digital, screen, flexo and offset print capabilities. LED inks are available to meet these various printing platform requirements.

Offering R&D Support

Some partners offer strong research and development support for customers and brands, providing the capabilities of tailor-made solutions that can help to meet necessary brand, industry and regional requirements, including environmental, lightweighting, weather and light resistance and more.

Larger partners have labs across the globe with dedicated R&D budgets for improving existing innovations, as well as designing new offerings for customers with specific needs.

Brands with specific sustainability needs can utilize these ink partnerships to develop a product that helps fit their individualized packaging requirements in order to reach their sustainability and package performance goals.

As brands carefully choose packaging partners who contribute to their sustainability goals, they’re searching for printers and ink manufacturers who can not only offer guidance, but act as experts and lead them in their push for sustainability.

By selecting partners who utilize raw materials, minimize waste, operate with efficiency in mind and offer R&D support, brands can put their consumers’ minds at ease and offer packaging that aligns with their sustainability needs.

Dennis Sweet is the Vice President of NWTL, Commercial, Rycoline and Distributors of North American Inks at Sun Chemical. Pete Bosque is a Field Marketing Manager of NWTL at Sun Chemical. Derrick Hemmings is the Product Manager of EC Flexo & LED NA & ECP Canada at Sun Chemical. For information on Sun Chemical’s sustainability initiatives, including its Center of Excellence, contact naimarketing@sunchemical.com.