Home » cartoning machine

Articles Tagged with ''cartoning machine''

Machinery Technology: Cartoning

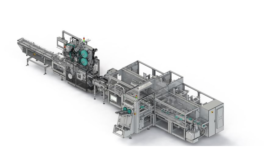

Improving Cartoning Changeover Capabilities

Advancements in technology offer packaging machine flexibility.

October 10, 2018

Machinery Technology: Cartoning

Today's cartoners are thinking outside the box

Horizontal or vertical, top or side, compact or full size, cartoners must offer flexibility and variety.

July 12, 2017

Machinery: Cartoning

The cartoning machinery kingdom

Efficiency and flexibility reign.

July 13, 2016

Supplier CloseUp: Propack

Flexible robotic collator & loader saves time, money and space

Take five with Propack Processing & Packaging Systems president Chris Follows.

March 12, 2015