Videojet Technologies (videojet.com) announced the launch of new thermochromic inks and high speed inks for continuous ink jet (CIJ) applications. A global leader in coding, marking and printing solutions, Videojet expands its robust line of high-performing inks to deliver superb print quality to manufacturers with the introduction of these inks.

“We’ve added to our ink lineup to offer customers ink solutions that not only provide excellent print quality, but that we believe are the best performers on the market for their particular applications. We strive to continually enhance our family of high-performing inks and tailor their properties to meet the specific demands of customer applications,” said Anthony Blencowe, Videojet Business Unit Director CIJ. “For example, the new thermochromic inks, which turn from black to blue after the retort process, penetrate tough surface deposits to give food manufacturers greater coding flexibility.”

V474/V519 thermochromic inks benefits and applications

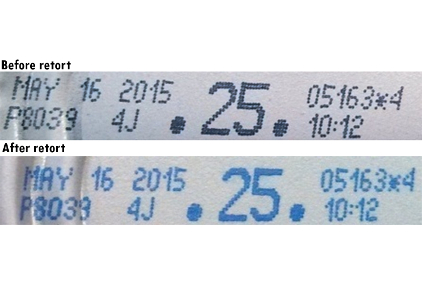

V474 and V519 black-to-blue inks add to the successful range of Videojet thermochromic inks designed to penetrate the toughest surface contaminations that may be present on cans in processed food filling lines. Recent advances in dye chemistry make it possible for these inks to penetrate waxy surface deposits and endure high temperature cooking processes while still achieving a distinctive color change.

After surviving the rigors of continuous flow retort cooking processes, the inks produce legible blue codes with high optical character recognition (OCR) read rates. These inks are added to the expanding Videojet lineup of MEK-free products. V474 is designed for use with CIJ printers in the Videojet 1000 Line, while V519’s unique properties make it suitable for use with Videojet 1620 and 1650 Ultra High Speed (UHS) printers.

V475/V520 thermochromic inks benefits and applications

The new V475 and V520 MEK-free formulated inks add to the Videojet spectrum of thermochromic high performance inks. The black-to-blue color change is easy to distinguish and adds peace of mind to the retort process. The unique dye composition enhances the shelf-life stability of the code under dry heat storage conditions that are very common throughout the retort processes.

The MEK-free formula uses alternative solvents, pentanone and ethanol, to enable relatively fast dry times on a variety of food containers substrates, such as metal cans, plastic pouches, bowls and glass jars.

V475 is designed for use with the Videojet 1000 Line of CIJ printers, while V520 is engineered to run on Videojet 1620 and 1650 UHS printers.

New inks for UHS printers – MEK-free universal black and fast dry dark gray

Videojet launched the 1620 and 1650 UHS printers in June 2013 along with a critical set of popular inks designed for high speed market applications. Now, in addition to V519 and V520, Videojet has released two other inks with unique properties for its 1620 and 1650 UHS printers. The addition of these new inks brings the total offering of Videojet high speed inks to 25.

- V538: Fast drying, dark gray ink engineered specifically for extruded PVC in cable and wire applications.

- V532: Ethanol-based, high quality MEK-like performance black ink for a broad variety of substrates.

Videojet tested these UHS inks and UHS printers for more than two years at the extremes of print speeds and environmental conditions. Designed for optimal drop formation, Videojet UHS inks and UHS printers help customers achieve excellent print quality at demanding production line speeds.