Unitizing/ Palletizing

Machinery Technology: Palletizing

Palletizing machinery gets refined

Efficiency, flexibility, speed and reliability are more than matters of taste.

July 15, 2015

Web exclusive

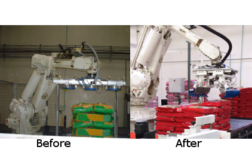

Retrofitting reliability

Replacing a competitor’s end-of-arm tool provides reliability on multiple levels

April 23, 2015

Cover Story: Robotics & Automation

Sophisticated robotics reveals new technology and controls to increase efficiencies

March 12, 2015