Nigel Smith

Nigel Smith is managing director of Toshiba Machine distributor, TM Robotics. www.tmrobotics.com.

ARTICLES

Cover Story: Automation & Robotics

Preparing for an Automated Future

Authorities in the field offer views on trends, new technology and more.

September 11, 2018

Machinery Technology: Robotics

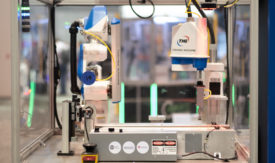

Robotic Solution for Food Packaging

Reduced size, higher speeds optimize automated loading system.

June 14, 2018