Home » Keywords: » food packaging technology

Items Tagged with 'food packaging technology'

ARTICLES

COVER STORY

Meat, Poultry, Seafood Packaging: Doing More with Less

Companies involved in the packaging of meat, poultry and seafood are highly aware of consumers’ concerns about sustainable packaging, and they are taking action.

August 3, 2023

Technology

3 Ways AI is Changing the Food Industry

AI technology continues to propel the food industry at a rapid pace.

April 12, 2022

Machinery

Selecting the Right Sanitary Conveyor Platform for Food Packaging Application

Conveyors are a prime target for contamination, but understanding the nuance of how equipment works with specific applications ensures upgrade success.

March 8, 2022

Spotlight Feature

Using IIoT to Improve Packaging Line Performance

Incremental implementation of the IIoT by plant engineers and other experts is the best route to success.

September 10, 2019

Materials

The Uprising of Inverted Pouches

Meet the new packaging format that is turning product categories upside down.

May 16, 2019

Automation

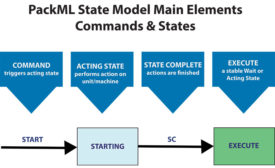

How 4 OEMs Implemented PackML

Four OEMs share their experiences implementing PackML in machine design and build.

May 15, 2019