Packaging Strategies recently spoke to three industry leaders in the area of inks and printing: INX International Ink Co., Domino, and HP Inc.

While offering their unique, individual perspectives, experts at all three companies touched on some common themes, including: reduced use of materials; the use of mono-material packaging to facilitate recycling; and providing flexibility to allow manufacturers to respond more quickly and efficiently to changes in print requirements.

The experts also touched on 1) the wide array of ink technology options for companies striving to meet increasingly stringent requirements for track-and-trace bar codes and 2) printing applications that meet the most demanding coding and marking requirements in food and pharmaceutical packaging.

Here are the enlightening and informative exchanges that we had with executives at the three companies.

RENEE SCHOUTEN, VICE PRESIDENT OF MARKETING FOR INX INTERNATIONAL INK CO.

Can you share some examples of the company’s recent initiatives in the areas of recyclability and sustainability?

Our Genesis GS Washable label inks make it easier to recycle films. Genesis is a solvent-based shrink ink for gravure and flexographic printing. Both are de-inkable from cPET films and floatable with roll-fed OPP labels in the recycling process.

GelFlex-EB Electron Beam Flexographic inks are solid, gel-based and fluid enough for superior CI flexo printing. GelFlex offers several important advantages. It eliminates a lamination layer for the reduced use of materials, it's easier to recycle, and you benefit from package lightweighting. The end result is you can produce vivid print designs with multi-colored palettes and different tactile packaging surfaces.

Furthermore, INX will be introducing a new oxygen barrier coating for mono-material packaging. When available, it will improve recycling and food preservation efforts.

What do you see coming down the road?

We anticipate seeing more innovations that target improvements in resource consumption. This would involve using natural-based, bio-renewable ingredients such as INXhrc, our eco-friendly high-performance inks for flexographic, offset and gravure purposes. It also includes the recycling arena with mono-material packaging to improve the recycling process.

CRAIG STOBIE, DIRECTOR OF GLOBAL STRATEGIC SECTORS, DOMINO PRINTING SCIENCES

Digital printing solutions are becoming increasingly popular within production environments. Domino’s Craig Stobie provided some examples of how the company’s digital solutions are helping manufacturers: respond to the latest consumer and regulatory demands; improve efficiency; and decrease manufacturing waste.

In-line digital printing and waste reduction

The pharmaceutical sector, and, in particular, blister pack printing is one example where in-line digital printing is helping manufacturers to reduce waste, improve efficiency, and increase line agility. Until recently, most pharmaceutical manufacturers would buy blister foils pre-printed with product names, dosage information, and branding and use a basic in-line printing or embossing system to add a batch code and expiry date to the blister in human-readable text.

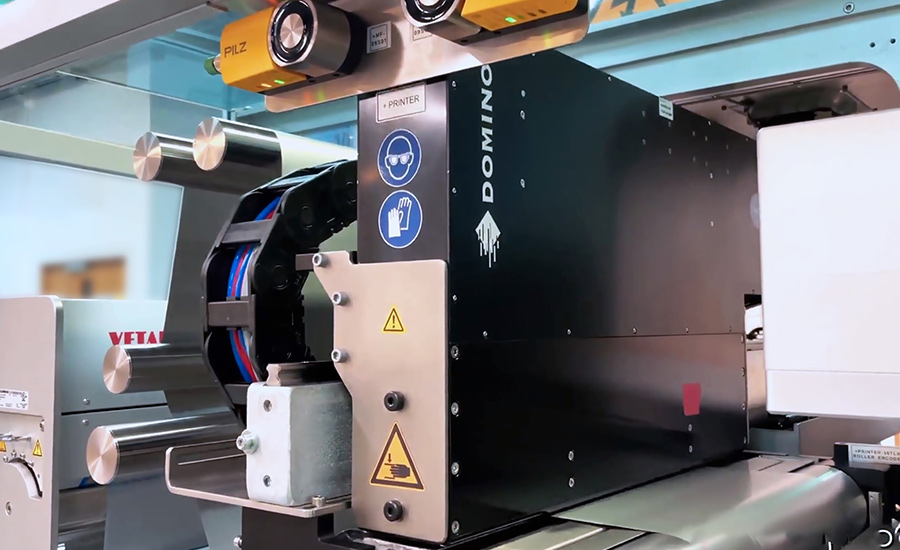

Introducing in-line digital printing, with applications such as Domino’s K600G, provides additional flexibility and can allow manufacturers to respond much more quickly and efficiently to changes in print requirements. In the past, manufacturers would typically have to wait several days or even weeks for pre-printed foils to arrive in the event of a change in product design. With in-line digital printing, manufacturers can switch from one design to the other in a fraction of the time. The technology also makes it economically viable to do much smaller batches.

Courtesy of Domino

When investing in a digital in-line printing solution, the price difference between a narrow printhead that is only suitable for printing variable information (i.e., 2D code, batch code, and expiry date), and a wider printhead that can also print larger graphics, including artwork, is often negligible compared with the possible savings. Wide web digital printing allows manufacturers to purchase only blank foils and carry out complete coding in-house, reducing stock requirements and inventory space. In addition, a significant saving can be made, as blank foils are less expensive than pre-printed, even when accounting for the cost of ink.

This new approach can also allow for significant waste reduction, helping pharmaceutical manufacturers reduce their environmental impact. Manufacturers typically order 10-20% extra when purchasing pre-printed foil to allow for unforeseen issues or wastage from set-up and product changeovers. However, in practice, they rarely need to use all the excess foil, and any excess may be discarded. This is not an issue with blank foils, as manufacturers can reuse excess foil for subsequent print runs.

Much development has been done in the last couple of years to increase the availability of suitable digital printing inks for pharmaceutical coding. UV curable inks are a standard application for metallic foil printing, and there are now many Swiss-List-approved, CMR-free variants available. There are also many water-based options suitable for paper-based packaging that deliver as much contrast as the classic UV drying inks – these are suitable for use in flexible papers, which are growing in popularity as blister pack seals.

Creative digital printing solutions to improve recyclability

Brands are under pressure to make their product packaging more recyclable and increase recycling rates. An area where Domino has seen significant attention recently, is in the creation of labelless PET bottles – created by brands to be more easily recyclable than bottles equipped with external labels or shrink wraps.

Labelless packaging can come with complications. Labelless bottles still need to adhere to regulatory labelling requirements and must display the proper information for consumer understanding — including communicating information on packaging composition and its recyclability.

As such, the move to labelless bottles necessitates innovative new methods of coding and marking bottles. Digital printing of bottles closures — or caps — is one such solution that is seeing significant interest from beverage manufacturers.

In-line and near-line digital printing solutions provide an option for manufacturers to print directly on bottle caps on labelless PET production lines. The small nature of bottle caps provides a suitable medium for simple branding and logos, as well as machine-readable codes — this can include barcodes, or scannable 2D codes to provide additional product information, including recycling information and guidance on how to dispose of the packaging correctly, traceability data, and promotional material.

Domino is currently working with several leading beverage brands to develop bespoke digital printing solutions, encompassing Domino’s K-Series range of digital printers, for in-line (pre- and post-fill), and near-line printing directly on bottle caps.

Courtesy of Domino

JOHN MEILING, SENIOR DIRECTOR – MARKETING & CATEGORY MANAGEMENT, OEM INKJET FOR SPECIALTY PRINTING SOLUTIONS, HP INC.

What is the current global landscape of safety regulations in the pharmaceutical and food industries?

Packaging and product identification processes in the pharmaceutical and food industries are becoming increasingly complex and sophisticated due to the growing threat and confusion from counterfeit and clone products available.

In response to this risk, national regulatory bodies like the U.S Food and Drug Administration (FDA), the European Food Safety Authority (EFSA), and European Medicines Agency (EMA) have made track-and-trace — the process of labelling, tracking, tracing, and documenting each consumer product along the supply chain and distribution channel to the final point of sale — a priority to protect consumers from illegitimate products and potentially hazardous materials entering the market.

This year alone, several countries, including India and Japan, have announced some form of mandate related to barcoding, traceability, and serialization. However, most of these systems have been designed and implemented with a local or regional focus. The next phase of track-and-trace must emphasize the importance of global interoperability if we are to protect public health from current and future threats along the entire global supply chain.

Why is specialty printing now essential for businesses to achieve consumer and patient safety?

Gaining end-to-end visibility into the supply chain and distribution of critical consumer goods, particularly ingestibles like food and pharmaceuticals, at any given time is one of the biggest safety levers companies have to pull to protect consumers and their brand image. With global regulations creating added requirements and time pressure, more companies are seeking compliance via specialty printing solutions using thermal inkjet (TIJ) technology, which offer high-resolution barcodes, QR codes, data matrices, as well as alphanumeric text that are scannable, legible, and durable across a wide range of packaging substrates.

Courtesy of HP Inc.

This level of high-speed, high-resolution print quality with high reliability and up-time makes TIJ technology one of the most favorable options in the food and pharmaceutical industries. The versatility and reliability it offers helps manufacturers guarantee that the printed product identification is non-toxic and will remain legible throughout the manufacturing and distribution process. Overlooking these issues could not only cause harm to consumers, but it could also lead to scrap and even manufacturing down-time, all of which impact the company’s bottom line.

How can new applications meet requirements for high resolution track-and-trace bar codes and compliant inks for package coding?

Thermal inkjet (TIJ) technology enables numerous printing applications, including those that meet the most demanding coding and marking requirements in food and pharmaceutical packaging environments.

Manufacturers can take advantage of versatile and GMP-compliant solvent inks as well as aqueous inks that print high resolution 2D barcodes, QR codes, data matrices and text, ideal for treated and untreated porous materials, polymer films, foils, and more. Depending on the product or need, TIJ technology can be deployed in innovative ways for specialty printing applications that meet evolving and increasingly stringent product safety and regulatory requirements for track-and-trace capabilities.