The glass container industry’s key indicators in North America remained generally stable between 2017 and 2018, with continued opportunities for growth in 2019 in the spirits, food and craft beverages markets.

Consumers continue to see glass as an eco-friendly package that is inert and ocean-friendly, 100 percent recyclable as well as reusable. Glass containers require no plastic or chemical liner, still perceived as best for taste and superior for creating premium and specialty experiences. Shipment and production data collected and aggregated by Precision Consulting show the U.S. glass container industry will have shipped around 27 billion containers to customers in 2018.

Beer

Changing consumer habits and market trends have left the beer market relatively flat, and competitive packaging remains a challenge given an increasingly on-the-go culture. Data for the first three quarters of 2018 show that beer remains the largest market segment, however it now represents 54 percent of the glass container industry’s sales volume (a drop of 2 percent in share from 2017).

Spirits, Wine, Food & Beverages

While shipments of beer bottles to customers are down slightly, glass containers for liquor and food increased. The food category, reflecting an increase in shipments to customers, accounts for 20 percent of the industry’s volume, followed by non-alcoholic beverages (10 percent) which grew 1 percent of share from 2016, liquor and ready-to-drink liquor (8 percent), and wine at 8 percent.

Imports & Exports

Imports of empty wine bottles (in the standard 750 ml format) and 12 oz. bottles increased, helping to meet customer demand in wine and key beverage categories. Exports of glass containers decreased slightly from recent highs in 2017, likely the result of new production manufacturing lines in the North American region.

Glass Manufacturing Facilities

In October 2018, Saverglass (saverglass.com) opened its Guadalajara, Mexico, plant to serve the growing tequila, mezcal, rum and spirits customer markets across North America and the Caribbean. Plant production is focused on packaging that can showcase these premium products, both in white flint and antique glass formats.

Glass Packaging & Market Trends

Consumer attitudes — along with growing market trends around transparency, sustainability and ocean-safe products and specialty and premium goods — present strong opportunities for glass containers.

Consumers continue to rank glass bottles number one for taste — 90 percent favor glass to best preserve the taste or flavor of the food and beverages, according to an EcoFocus Worldwide 2017 survey. Glass is the most neutral and natural of packaging materials, with an almost zero rate of chemical interaction, ensuring product integrity, and preserving and presenting flavor exactly as intended.

With consumers more educated and mindful about what they put in their bodies, ensuring product integrity is critical. Brands that are making organic, clean label and other “functional” products, a growing market category, want a natural and transparent package to match. Unlike cans, drink boxes, pouches, and other food and beverage packaging, glass bottles and jars are the only packaging that doesn’t require a plastic or chemical liner that may affect the taste of food — and consumer health.

As premiumization grows in all categories — especially wine and spirits — no other packaging material matches glass for a premium consumer experience. Design attributes only possible with glass offer an exceptional package. Glass bottles with thick bases, embossing and decoration work together with label designs to present a harmonized, high-quality image that convey the story of the brand and offer unmatched shelf presence.

Texture is also an important design trend. Glass has always been a tactile medium and can be leveraged to include micro-textures that communicate where to grip, hold and pour, as well as signature elements like logos and graphics. More than ever, brands are seeking to push the envelope when it comes to texture, incorporating textured paper labels, shrink sleeves, textured inks, molded or embossed closures and more.

The design qualities of glass packaging are showcased in the 2018 Clear Choice Awards winners. This competition, which recognizes glass packaging used by North America’s top brands and manufacturers, named winners in seven categories, including a new “sustainability” category. Gruppo Campari’s Wild Turkey Longbranch took top honors in the Wine and Spirits category and also captured the overall award.

Recyclable, Refillable & Ocean Friendly

The desire for sustainable packaging is a high value for consumers. In a fall 2018 survey by G&S Business Communications, glass bottles and jars came out on top (57 percent) as the packaging U.S. consumers believe is most sustainable, followed by corrugated boxes (51 percent), metal cans (38 percent), flexibles (37 percent) and plastic (34 percent).

Glass is also ocean friendly. Because glass bottle and jars are primarily made from sand and other natural ingredients, they don’t harm oceans or marine life. Glass bottles are 100 percent recyclable, safe and non-toxic, with recycling programs for glass available to 81 percent of the U.S. population. Recycled content in glass bottles is also maximized in markets where the quality, price and availability allow that to occur.

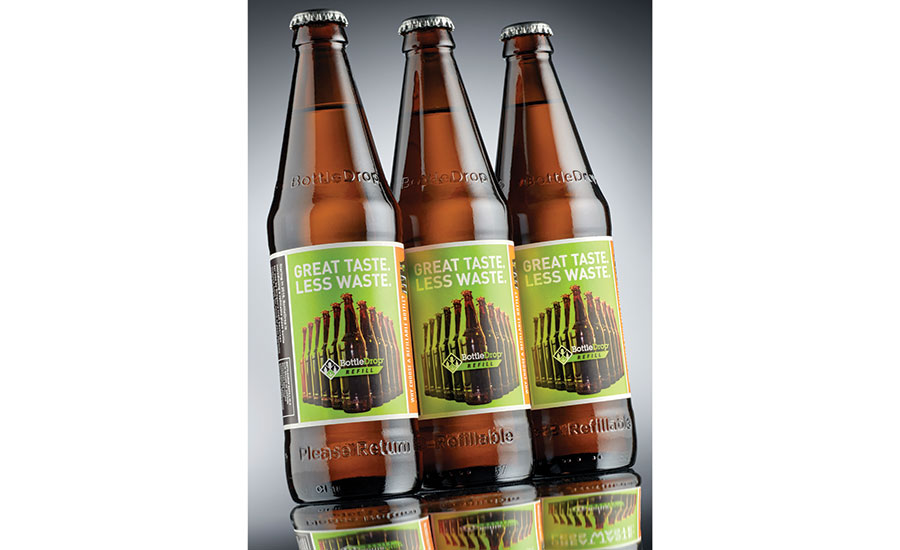

While consumers know that glass is endlessly recyclable, reusable and resealable, 2018 saw a surge in the refillable bottle market. Piloted in 2017, the BottleDrop refillable glass bottle officially launched in 2018 as the world’s most sustainable package. Led by the Oregon Beverage Recycling Cooperative’s refillable beer bottle program — featuring O-I’s (o-i.com) Portland, Ore., produced bottle — the initiative partners with eight Oregon breweries.

Consumers are encouraged to return, rather than recycle, these 500 ml and 12 oz. beer bottles, which can be customized with label and closure. These refillable bottles can be used 25 times before being retired from circulation and recycled into new containers, while delivering up to 66 times less CO2 emissions per container than aluminum cans. The cost per filling is also reduced over the lifetime of the bottle.

Looking Ahead

The industry’s economic indicators are steady, and consumer sentiment shows glass remains on top as the packaging of choice for taste, health and sustainability. Glass manufacturers remain ready to offer more operational flexibility, including smaller batches and rapid response, as well as continued lightweighting. They are also positioned to respond to brands seeking to inspire new occasions for consumption by offering new capacity sizes — both smaller as well as larger and shareable. Finally, glass packaging remains in the unique position to capitalize on premium and specialty experiences, which remain on-trend across product categories.

Executive Summary

|

Packaging Outlook 2019 Articles:

|